- Produit Numm: SNMG Inserts

- Serie: SNMG

- Chip-Breakers: AM/AR/BF/BM/BR/CM/DM

Beschreiwung

Produkt Informatioun:

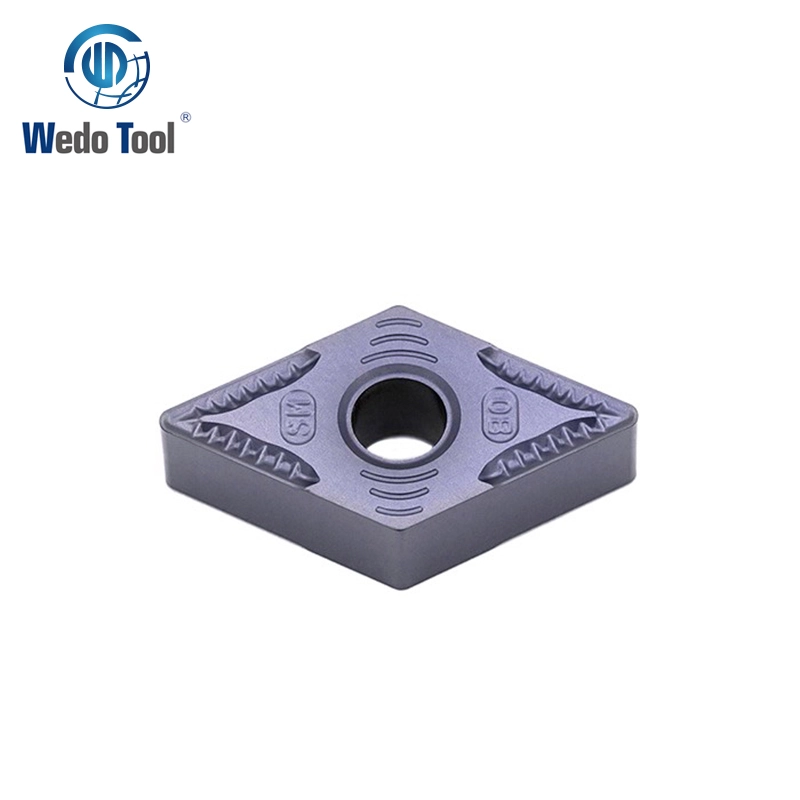

Turing asetzen SNMG. Duebelsäiteg 90 ° Quadrat Inserts. 0 Grad Relief Wénkel. Solid Carbide Handwierksgeschir bidden laang Tool Liewen a méi séier Schneidgeschwindegkeet wéi aner Substrate, awer si méi brécheg a musse mat steife Toolhaltersystemer benotzt ginn. Benotzt op eng breet Palette vu Materialien an Uwendungen.

Spezifikatioune:

Applikatioun | Typ | Ap (mm) | Fn (mm/v) | Grad | |||||||||||

CVD | PVD | ||||||||||||||

WD4215 | WD4315 | WD4225 | WD4325 | WD4235 | WD4335 | WD1025 | WD1325 | WD1525 | WD1328 | WR1010 | WR1325 | ||||

P Semi Finishing | SNMG120404-AM | 1.00-5.00 | 0.12-0.40 | ● | O | ● | O | O | |||||||

SNMG120408-AM | 1.20-5.00 | 0.15-0.55 | ● | O | ● | O | O | ||||||||

SNMG120412-AM | 1.50-5.00 | 0.20-0.55 | ● | O | ● | O | O | ||||||||

SNMG150612-AM | 2.00-7.00 | 0.30-0.65 | ● | O | ● | O | O | ||||||||

●: Recommandéiert Grad

O: Optional Grad

Applikatioun | Typ | Ap (mm) | Fn (mm/v) | Grad | |||||||||||

CVD | PVD | ||||||||||||||

WD4215 | WD4315 | WD4225 | WD4325 | WD4235 | WD4335 | WD1025 | WD1325 | WD1525 | WD1328 | WR1010 | WR1325 | ||||

P Rau Machining | SNMG120408-AR | 2.50-6.00 | 0.25-0.70 | ● | O | ||||||||||

SNMG120412-AR | 2.50-6.00 | 0.30-0.70 | ● | O | |||||||||||

SNMG120416-AR | 2.50-6.00 | 0.40-0.70 | ● | O | |||||||||||

SNMG150612-AR | 2.15-6.40 | 0.25-0.50 | ● | O | |||||||||||

SNMG190612-AR | 2.15-6.40 | 0.25-0.50 | ● | O | |||||||||||

SNMG190616-AR | 2.85-7.60 | 0.30-0.65 | ● | O | |||||||||||

●: Recommandéiert Grad

O: Optional Grad

Applikatioun | Typ | Ap (mm) | Fn (mm/v) | Grad | |||||||||||

CVD | PVD | ||||||||||||||

WD4215 | WD4315 | WD4225 | WD4325 | WD1025 | WD1325 | WD1525 | WD1328 | WR1010 | WR1325 | WR1525 | WR1330 | ||||

M Ofschloss | SNMG120404-BF | 0.25-3.20 | 0.05-0.15 | ● | ● | O | O | ||||||||

SNMG120408-BF | 0.50-3.20 | 0.10-0.30 | ● | ● | O | O | |||||||||

SNMG120412-BF | 0.75-3.20 | 0.15-0.45 | ● | ● | O | O | |||||||||

●: Recommandéiert Grad

O: Optional Grad

Applikatioun | Typ | Ap (mm) | Fn (mm/v) | Grad | |||||||||||

CVD | PVD | ||||||||||||||

WD4215 | WD4315 | WD4225 | WD4325 | WD1025 | WD1325 | WD1525 | WD1328 | WR1010 | WR1325 | WR1525 | WR1330 | ||||

M Semi Finishing | SNMG120404-BM | 0.30-4.20 | 0.08-0.25 | O | O | ● | O | O | |||||||

SNMG120408-BM | 0.65-4.20 | 0.15-0.45 | O | O | ● | O | O | ||||||||

SNMG120412-BM | 0.95-4.20 | 0.25-0.65 | O | O | ● | O | O | ||||||||

SNMG150608-BM | 0.65-5.20 | 0.15-0.45 | O | O | ● | O | O | ||||||||

SNMG150612-BM | 0.95-5.20 | 0.25-0.65 | O | O | ● | O | O | ||||||||

●: Recommandéiert Grad

O: Optional Grad

Applikatioun | Typ | Ap (mm) | Fn (mm/v) | Grad | |||||||||||

CVD | PVD | ||||||||||||||

WD4215 | WD4315 | WD4225 | WD4325 | WD1025 | WD1325 | WD1525 | WD1328 | WR1010 | WR1325 | WR1528 | WR1330 | ||||

M Rau Machining | SNMG120404-BR | 0.30-4.20 | 0.08-0.25 | O | O | O | ● | ● | O | ||||||

SNMG120408-BR | 0.65-4.20 | 0.15-0.45 | O | O | O | ● | ● | O | |||||||

SNMG120412-BR | 0.95-4.20 | 0.23-0.66 | O | O | O | ● | ● | O | |||||||

SNMG150608-BR | 0.65-5.20

| 0.15-0.44 | O | O | O | ● | ● | O | |||||||

SNMG150612-BR | 0.95-5.20 | 0.23-0.66 0.23-0.66 | O | O | O | ● | ● | O | |||||||

●: Recommandéiert Grad

O: Optional Grad

Applikatioun | WD3040 | Ap (mm) | Fn (mm/v) | Grad | |||

CVD | |||||||

WD3020 | WD3040 | WD3315 | WD3415 | ||||

K Semi Ofschloss | SNMG120404-CM | 0.40-4.20 | 0.08-0.25 | ● | O | ||

SNMG120408-CM | 0.80-4.20 | 0.15-0.45 | ● | O | |||

SNMG120412-CM | 1.20-4.20 | 0.25-0.65 | ● | O | |||

●: Recommandéiert Grad

O: Optional Grad

Applikatioun | Typ | Ap (mm) | Fn (mm/v) | Grad | ||||||||||||

CVD | PVD | |||||||||||||||

WD4215 | WD4315 | WD4225 | WD4325 | WD1025 | WD1325 | WD1525 | WD1328 | WR1010 | WR1520 | WR1525 | WR1028 | WR1030 | ||||

S Semi Finishing | SNMG120404-DM | 0.40-3.90 | 0.08-0.25 | O | O | O | ● | ● | O | O | ||||||

SNMG120408-DM | 0.80-3.90 | 0.15-0.45 | O | O | O | ● | ● | O | O | |||||||

SNMG120412-DM | 1.20-3.90 | 0.25-0.65 | O | O | O | ● | ● | O | O | |||||||

SNMG120416-DM | 1.80-3.90 | 0.30-0.90 | O | O | O | ● | ● | O | O | |||||||

SNMG150608-DM | 0.80-3.90 | 0.15-0.45 | O | O | O | ● | ● | O | O | |||||||

SNMG150612-DM | 1.20-3.90 | 0.25-0.65 | O | O | O | ● | ● | O | O | |||||||

SNMG150616-DM | 1.80-3.90 | 0.30-0.90 | O | O | O | ● | ● | O | O | |||||||

●: Recommandéiert Grad

O: Optional Grad

Applikatioun:

Uwendung fir Dréien a Fräsen vu Kuele- a Legierungsstahl, Tools Stol an Edelstol.

FAQ:

Wéi wielen ech de richtege Wendungsinsert?

Wielt Insert Geometrie baséiert op ausgewielt Operatioun, zum Beispill Ofschloss.

Wielt de gréisste méigleche Nueswénkel op der Insert fir Kraaft a Wirtschaft.

Wielt d'Insertgréisst jee no der Tiefe vum Schnëtt

Wielt de gréisste méigleche Nuesradius fir d'Insertstäerkt.

Wat ass den Ënnerscheed tëscht Gesiichtsfräsen an Ennfräsen?

Dëst sinn zwee vun de stäerkste verbreet milling Operatiounen, all benotzt verschidden Zorte vu cutters - der a Millen an der Gesiicht Millen. Den Ënnerscheed tëscht Ennfräsen a Gesiichtsfräsen ass datt eng Endmillen souwuel d'Enn wéi och d'Säite vum Cutter benotzt, wärend Gesiichtsfräsen fir horizontal Ausschneiden benotzt gëtt.

Hot Tags: snmg Inserts, dréinen,Fräsen, Ausschneiden, Grooven, Fabréck,CNC