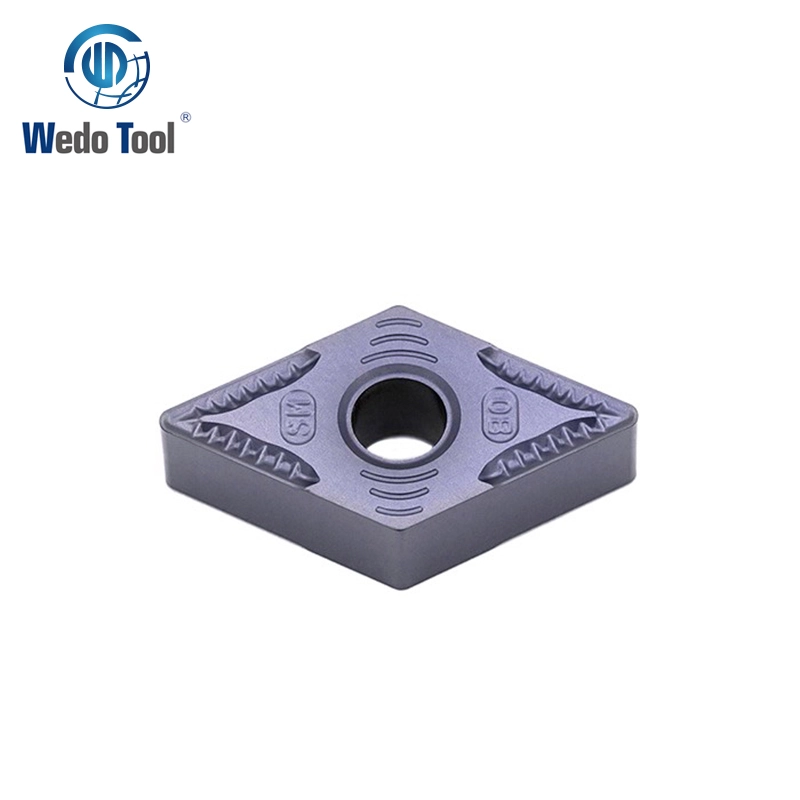

- Produit Numm: WNMG Inserts

- Serie: WNMG

- Chip-Breakers: AM/AR/BF/BM/BR/CM/DM/

Broessdatsch

Produkt Informatioun:

WNMG Turning Inserts mat negativen (0°) Reliefwénkel, hunn staark Kante. Déi allgemeng Uwendungen a variéierend Schnëttdéiften ofhängeg vum Chipbreaker Typ iwwer déi meescht Materialien. WNMG Turning Inserts kënne mat multiple Operatiounen ëmgoen andeems verschidde Chipbrecher a Graden kombinéiert ginn. et ass eng ganz gutt ekonomesch Wiel fir Är Produktioun, well se symmetresch gemaach ginn, sou datt wann dee Schnëtt gedroen ass, kënnen se op eng aner Rand rotéieren.

Spezifikatioune:

Applikatioun | Typ | Ap (mm) | Fn (mm/v) | Grad | |||||||||||

CVD | PVD | ||||||||||||||

WD 4215 | WD 4315 | WD 4225 | WD 4325 | WD 4235 | WD 4335 | WD 1025 | WD 1325 | WD 1525 | WD 1328 | WR 1010 | WR 1325 | ||||

P Semi Finishing | WNMG080404-AM | 0.60-4.30 | 0.10-0.30 | ● | O | ● | O | O | |||||||

WNMG080408-AM | 1.20-4.30 | 0.20-0.60 | ● | O | ● | O | O | ||||||||

WNMG080412-AM | 1.80-4.30 | 0.30-0.90 | ● | O | ● | O | O | ||||||||

WNMG080416-AM | 2.40-4.30 | 0.40-1.20 | ● | O | ● | O | O | ||||||||

●: Recommandéiert Grad

O: Optional Grad

Applikatioun | Typ | Ap (mm) | Fn (mm/v) | Grad | |||||||||||

CVD | PVD | ||||||||||||||

WD 4215 | WD 4215 | WD 4225 | WD 4325 | WD 4235 | WD 4335 | WD 1025 | WD 1325 | WD 1525 | WD 1328 | WR 1010 | WR 1325 | ||||

P Rau Machining | WNMG060408-AR | 0.80-4.00 | 0.15-0.50 | ● | O | ||||||||||

WNMG060412-AR | 0.80-4.00 | 0.15-0.50 | ● | O | |||||||||||

WNMG080408-AR | 0.80-4.50 | 0.15-0.55 | ● | O | |||||||||||

WNMG080412-AR | 0.80-4.50 | 0.20-0.55 | ● | O | |||||||||||

●: Recommandéiert Grad

O: Optional Grad

Applikatioun | Typ | Ap (mm) | Fn (mm/v) | Grad | |||||||||||

CVD | PVD | ||||||||||||||

WD 4215 | WD 4315 | WD 4225 | WD 4325 | WD 1025 | WD 1325 | WD 1525 | WD 1328 | WR 1010 | WR 1325 | WR 1525 | WR 1330 | ||||

M Ofschloss | WNMG060404-BF | 0.25-2.40 | 0.05-0.15 | ● | ● | O | O | ||||||||

WNMG060408-BF | 0.50-2.40 | 0.10-0.30 | ● | ● | O | O | |||||||||

WNMG080404-BF | 0.25-3.20 | 0.05-0.15 | ● | ● | O | O | |||||||||

WNMG080408-BF | 0.50-3.20 | 0.10-0.30 | ● | ● | O | O | |||||||||

WNMG080412-BF | 0.75-3.20 | 0.15-0.45 | ● | ● | O | O | |||||||||

WNMG080416-BF | 1.05-3.20 | 0.20-0.60 | ● | ● | O | O | |||||||||

●: Recommandéiert Grad

O: Optional Grad

Applikatioun | Typ | Ap (mm) | Fn (mm/v) | Grad | |||||||||||

CVD | PVD | ||||||||||||||

WD 4215 | WD 4315 | WD 4225 | WD 4325 | WD 1025 | WD 1325 | WD 1525 | WD 1328 | WR 1010 | WR 1325 | WR 1525 | WR 1330 | ||||

M Semi Finishing | WNMG060404-BM | 0.30-2.10 | 0.10-0.30 | O | O | ● | O | O | |||||||

WNMG060408-BM | 0.65-2.10 | 0.15-0.45 | O | O | ● | O | O | ||||||||

WNMG080404-BM | 0.30-2.90 | 0.10-0.30 | O | O | ● | O | O | ||||||||

WNMG080408-BM | 0.65-2.90 | 0.15-0.45 | O | O | ● | O | O | ||||||||

WNMG080412-BM | 0.95-2.90 | 0.20-0.60 | O | O | ● | O | O | ||||||||

WNMG080416-BM | 1.25-2.90 | 0.25-0.75 | O | O | ● | O | O | ||||||||

●: Recommandéiert Grad

O: Optional Grad

Applikatioun | Typ | Ap (mm) | Fn (mm/v) | Grad | |||||||||||

CVD | PVD | ||||||||||||||

WD 4215 | WD 4315 | WD 4225 | WD 4325 | WD 1025 | WD 1325 | WD 1525 | WD 1328 | WR 1010 | WR 1325 | WR 1528 | WR 1330 | ||||

M Rau Machining | WNMG060404-BR | 0.30-2.10 | 0.10-0.30 | O | O | O | ● | ● | O | ||||||

WNMG060408-BR | 0.65-2.10 | 0.15-0.45 | O | O | O | ● | ● | O | |||||||

WNMG080404-BR | 0.30-2.90 | 0.10-0.30 | O | O | O | ● | ● | O | |||||||

WNMG080408-BR | 0.65-2.90 | 0.15-0.45 | O | O | O | ● | ● | O | |||||||

WNMG080412-BR | 0.95-2.90 | 0.20-0.60 | O | O | O | ● | ● | O | |||||||

WNMG080416-BR | 1.25-2.90 | 0.25-0.75 | O | O | O | ● | ● | O | |||||||

●: Recommandéiert Grad

O: Optional Grad

Applikatioun | Typ | Ap (mm) | Fn (mm/v) | Grad | |||

CVD | |||||||

WD3020 | WD3040 | WD3315 | WD3415 | ||||

K Semi Ofschloss | WNMG080404-CM | 0.08-0.25 | 0.40-2.90 | ● | ● | ||

WNMG080408-CM | 0.15-0.45 | 0.80-2.90 | ● | ● | |||

WNMG080412-CM | 0.25-0.66 | 1.20-2.90 | ● | ● | |||

• : Recommandéiert Grad

O: Optional Grad

Applikatioun | Typ | Ap (mm) | Fn (mm/v) | Grad | ||||||||||||

CVD | PVD | |||||||||||||||

WD 4215 | WD 4315 | WD 4225 | WD 4325 | WD 1025 | WD 1325 | WD 1525 | WD 1328 | WR 1010 | WR 1520 | WR 1525 | WR 1028 | WR 1330 | ||||

S Semi Finishing | WNMG080404-DM | 0.40-4.30 | 0.08-0.25 | O | O | O | ● | ● | O | O | ||||||

WNMG080408-DM | 0.80-4.30 | 0.15-0.45 | O | O | O | ● | ● | O | O | |||||||

WNMG080412-DM | 1.20-4.30 | 0.25-0.66 | O | O | O | ● | ● | O | O | |||||||

WNMG080416-DM | 1.60-4.30 | 0.30-0.90 | O | O | O | ● | ● | O | O | |||||||

●: Recommandéiert Grad

O: Optional Grad

Applikatioun:

Dës WNMG Turning Inserts kënne mat multiple Operatiounen ëmgoen andeems verschidde Chipbrecher a Graden kombinéiert ginn. Recommandéiert fir rau, semi-finishing an Ofbau vun machining meeschte Stol, STAINLESS Stol, Goss an super Legierungen ënner stabile Konditiounen.

FAQ:

Wat ass den Ënnerscheed tëschtnegativanpositivinserts?

Den Ënnerscheed tëschtNegativanPositivinsert läit an si mat verschiddene Spillraum Wénkel.Déi positiv Inserts hunn e Spillwénkel tëscht 1 Grad an 90 Grad.De Clearance Wénkel vum negativen Insert ass o Grad.

Wéi eng Inserttyp ass déi bescht Wiel fir rau Machining?

When you need roughing and general turning .déi negativ Inserts sinn déi éischt a bescht Optioun. Negativ Insert erlaabt méi déif Déiften a méi héije Feedraten wéinst staarken Insertformen an Dicke.

Hot Tags: WNMG Insert,dréinen,milling, cutting, grooving, factory, wnmg 0804, wnmg insert angle, wnmg 080404, wnmg06