tlhaloso

Lintlha tsa Sehlahisoa:

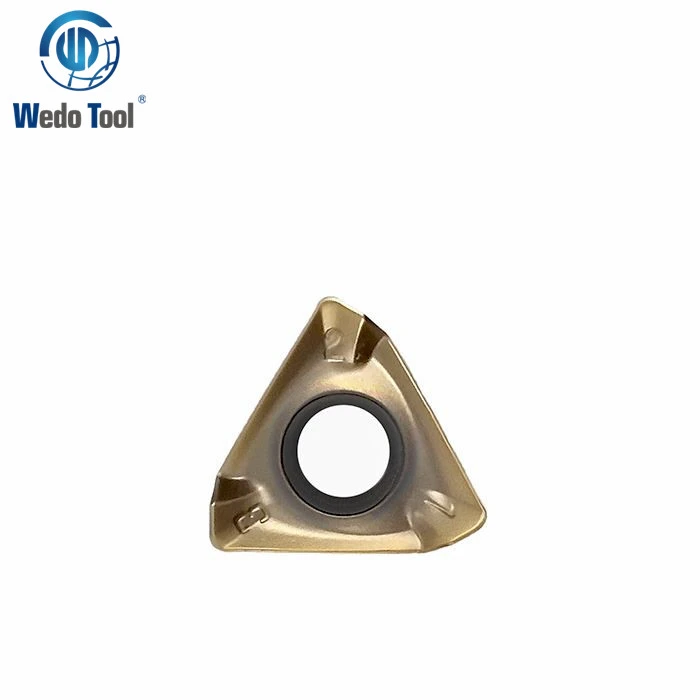

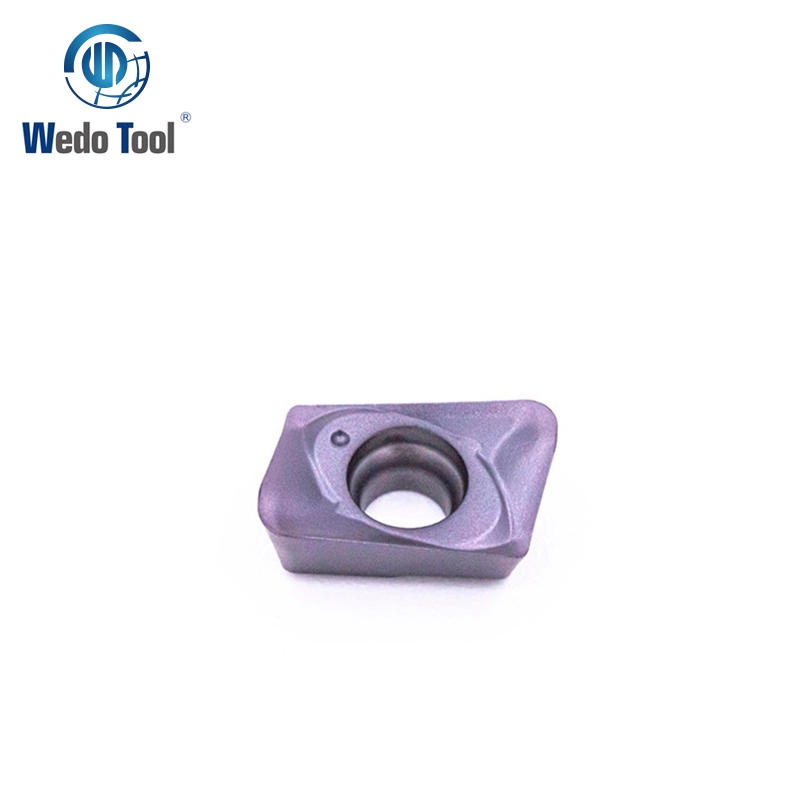

90° Shoulder Milling Insert e nang le likarolo tse tharo tse khathollang ke e ntle haholo e kentsoeng ka mokhoa o phahameng oa helical cutting edge. 90° ho sila ka mahetla ka machining a boreleli haholo le a bonolo ho fana ka tlhahiso e phahameng ka bongata ba meno. 'Mele o matla oa sesebelisoa o nang le boholo bo boholo ba mantlha, tse fapaneng tse kenyelletsang geometry.

TPKT standard carbide (e nang le coating) li-milling tse kentsoeng li na le likarolo tse matla tsa ho itšeha, tse fanang ka ts'epo e ntle le mamello e telele.

T - sebopeho sa kgutlotharo sa ho kenya sila

P - Kenya ka tumello tlas'a moeli o ka sehloohong (11 °).

K- Mamello le litekanyo tsa carbide

T - Hole ka har'a ho kenya le seqhetso sa chip se nang le lehlakore le le leng.

Litlhaloso:

Mofuta | Ap (mm) | Fn (mm/rev) | CVD | PVD | |||||||||

WD 3020 | WD 3040 | WD 1025 | WD 1325 | WD 1525 | WD 1328 | WR 1010 | WR 1520 | WR 1525 | WR 1028 | WR 1330 | |||

TPKT040202R-M | 0.50-3.00 | 0.04-0.08 | ● | ● | O | O | |||||||

TPKT040204R-M | 0.50-3.00 | 0.04-0.08 | ● | ● | O | O | |||||||

TPKT060302R-M | 1.00-4.00 | 0.04-0.10 | ● | ● | O | O | |||||||

TPKT060304R-M | 1.00-4.00 | 0.04-0.10 | ● | ● | O | O | |||||||

TPKT060308R-M | 1.00-4.00 | 0.04-0.10 | ● | ● | O | O | |||||||

TPKT100404R-M | 2.00-6.00 | 0.05-0.12 | ● | ● | O | O | |||||||

TPKT100408R-M | 2.00-6.00 | 0.05-0.12 | ● | ● | O | O | |||||||

TPKT100416R-M | 2.00-6.00 | 0.05-0.12 | ● | ● | O | O | |||||||

TPKT150508R-M | 3.00-9.00 | 0.07-0.17 | ● | ● | O | O | |||||||

TPKT150516R-M | 3.00-9.00 | 0.07-0.17 | ● | ● | O | O | |||||||

TPKT150524R-M | 3.00-12.00 | 0.07-0.17 | ● | ● | O | O | |||||||

TPKT190608R-M | 4.50-12.00 | 0.09-0.22 | ● | ● | O | O | |||||||

TPKT190616R-M | 4.50-12.00 | 0.09-0.22 | ● | ● | O | O | |||||||

TPKT190624R-M | 4.50-12.00 | 0.09-0.22 | ● | ● | O | O | |||||||

TPKT190632R-M | 4.50-12.00 | 0.09-0.22 | ● | ● | O | O | |||||||

●: Kereiti e khothalelitsoeng

O: Kereiti ya boikgethelo

Lisebelisoa:

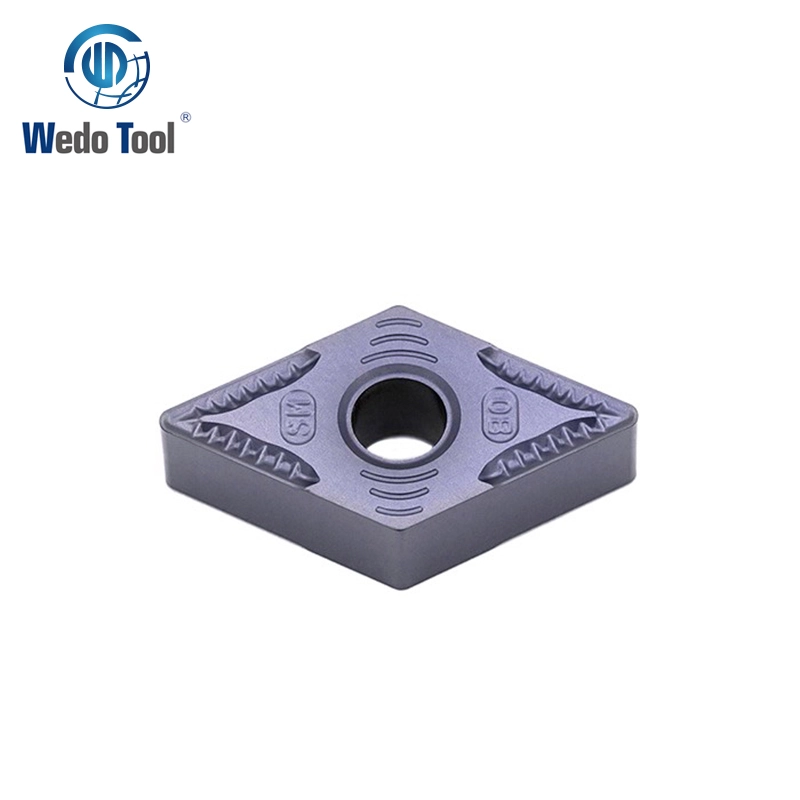

Bakeng sa machining ka kakaretso, tšepe e sa hloekang le machining a bobebe a nang le bohale bo bohale, lisebelisoa tsa tšepe le tse se nang ferrous, chip splitter insert.E sebelisoa haholo ho sebelisoa ha leseli le bohareng & ka machining a tšepe e sa hloekang.

LBH:

Ho sila mahetla ke eng?

Ho sila ka mahetla ho hlahisa lifahleho tse peli ka nako e le 'ngoe, tse hlokang ho siloa ha peripheral hammoho le ho sila sefahleho. Ho sila ka mahetla ho ka etsoa ke batho ba setso ba sehang mahetleng a lisekoere, hape ka ho sebelisa li-cut cutters, li-cutters tse bolelele bo bolelele le li-cutters tsa mahlakoreng le sefahleho.

Ke mokhoa ofe oa ho sila o khothalletsoang ka kakaretso?

Ka kakaretso, ho roala fatše ho khothaletsoa. Ka mokhoa oa ho sila fatše, phello e tukang e ka qojoa, e bakang mocheso o fokolang le mokhoa o fokolang oa ho thatafatsa mosebetsi.

Wedo CuttingTools Co,.Ltde tsebahala haholo e le e mong oa ba etellang peleho kenya carbidebarekisi ba China.Lihlahisoa tse kholo tsa k'hamphani keho thinya tse kenyang,Lisebelisoa tsa ho sila,Lisebelisoa tsa ho cheka, lintho tse kenyang khoele, li-grooving inserts leqetellong leloala.