tlhaloso

Lintlha tsa Sehlahisoa:

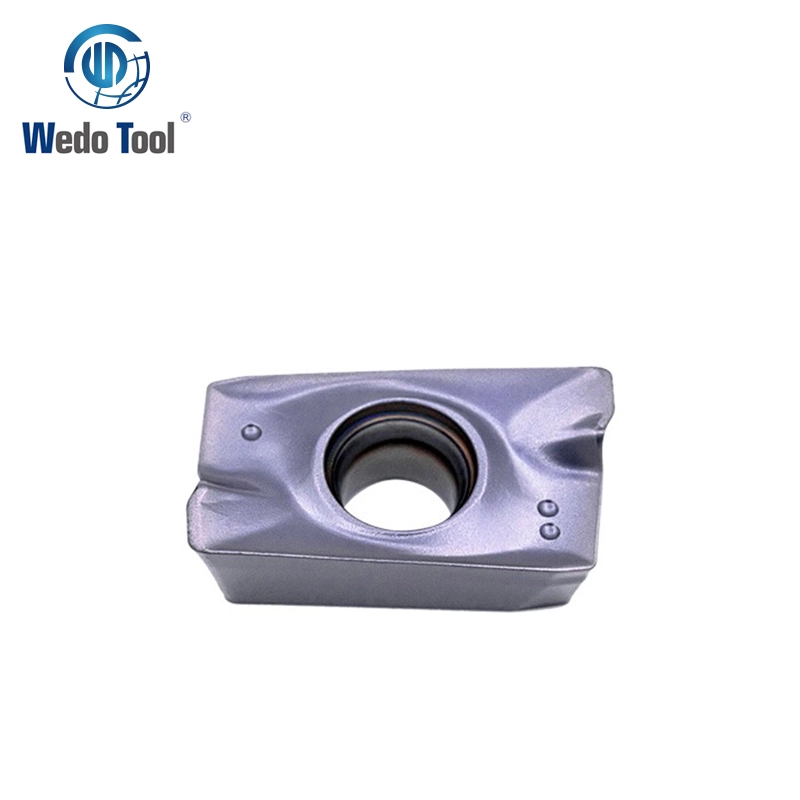

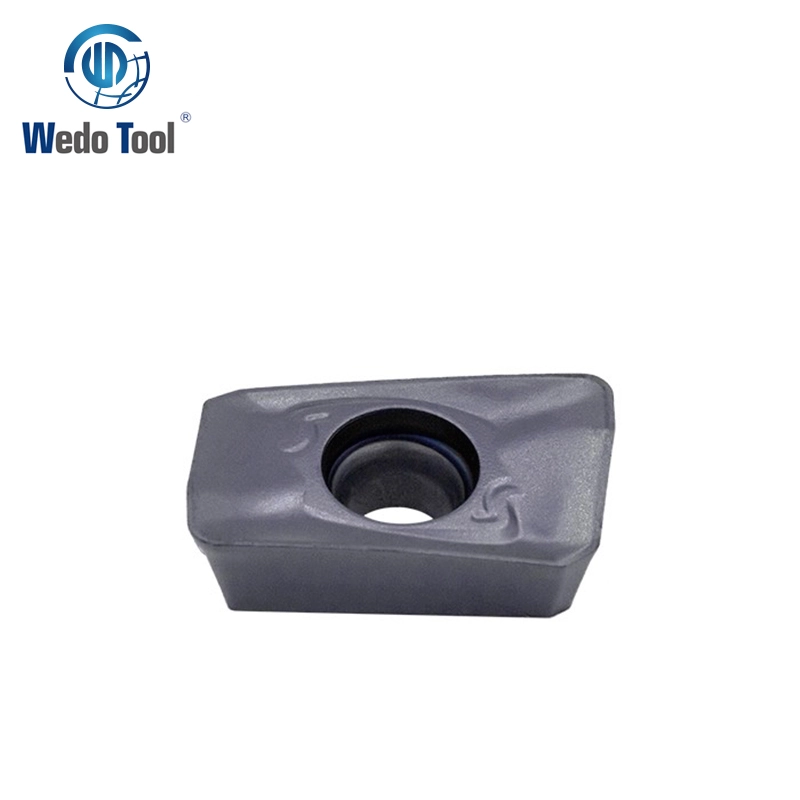

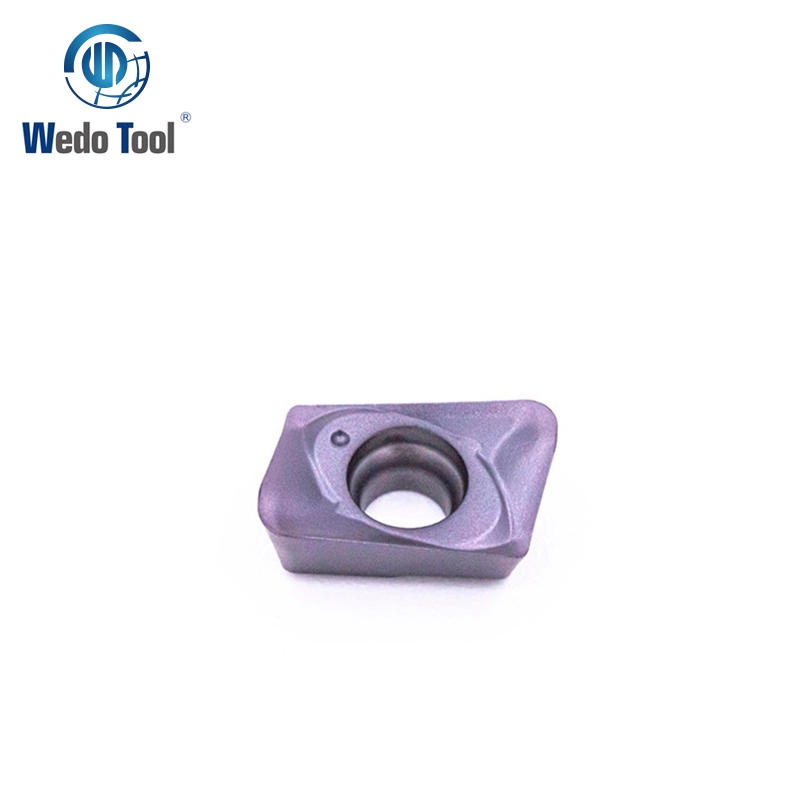

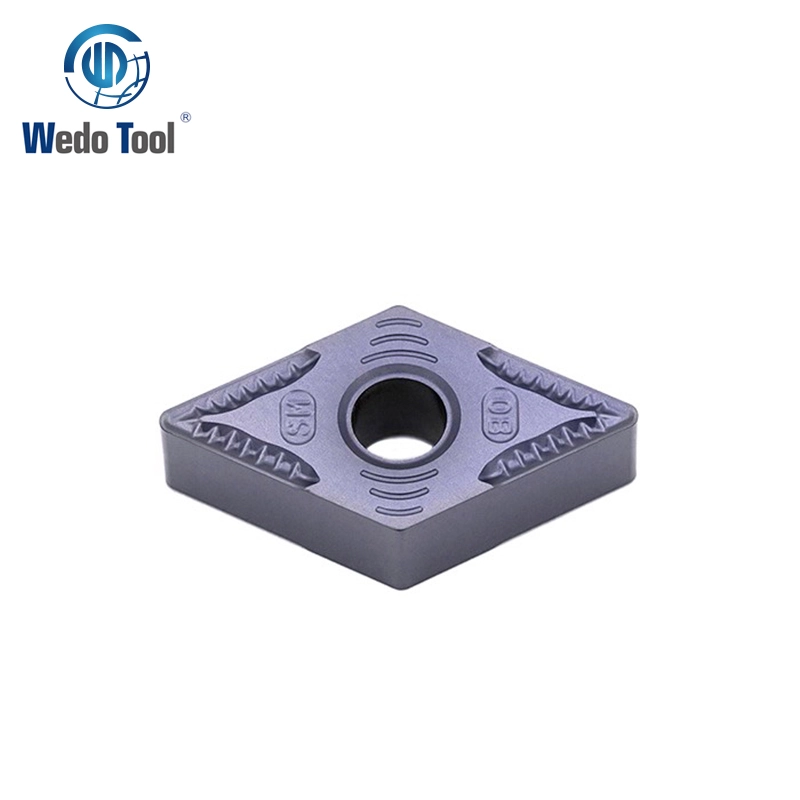

Lisebelisoa tsa Carbide APMT PVD tse koahetsoeng hangata li sebelisoa bakeng sa li-cutters tsa ho qetela tsa lisekoere tsa mahetla le li-cutter tsa sefahleho. Lisebelisoa tsa APMT li na le I.C. e entsoeng ka mokhoa o nepahetseng, e bōpehileng hantle. Li na le moeli o bohale le o nang le bohloeki le angle ea liphallelo ea 11 °. Li na le masoba a screw a entsoeng ho latela ISO. Ka tloaelo, e talingoa joalo ka lithapo tse 2 tsa ho itšeha. Leha ho le joalo, li na le likarolo tse 4 tsa ho itšeha. ha li kentsoe ho li-milling cutters tsa 90° indexable indexable cutters 'me mahlakore ka bobeli a ba lerootho, a ka kengoa ho li-milling cutters tse 75° Â 'me a tsoele pele ho sebelisa lits'ebetso tse ling ka mahlakore a mang a mabeli.APMT e tla ba khetho e ntle bakeng sa basebelisi ba ho qetela, kaha e e ka ntlafatsa haholo tlhahiso.

Litlhaloso:

Mofuta | Ap (mm) | Fn (mm/rev) | CVD | PVD | |||||||||

WD3020 | WD3040 | WD1025 | WD1325 | WD1525 | WD1328 | WR1010 | WR1520 | WR1525 | WR1028 | WR1330 | |||

APMT1135PDER-XR | 2.50-7.50 | 0.05-0.25 | • | • | O | O | |||||||

APMT1605PDER-XR | 3.50-10.00 | 0.07-0.50 | • | • | O | O | |||||||

APMT1135PDER-M2 | 2.50-7.50 | 0.05-0.25 | • | • | O | O | |||||||

APMT160408PDER-M2 | 3.50-10.00 | 0.07-0.30 | • | • | O | O | |||||||

APMT1135PDER-GM | 2.50- 7.50 | 0.05-0.25 | • | • | O | O | |||||||

APMT160408PDER-GM | 3.50-10.00 | 0.07-0.50 | • | • | O | O | |||||||

APMT1135PDER-H2 | 2.50-7.50 | 0.05-0.25 | • | • | O | O | |||||||

APMT160408PDER-H2 | 3.50-10.00 | 0.07-0.30 | • | • | O | O | |||||||

• : Kereiti e khothaletsoang

O: Kereiti ya boikgethelo

Kopo:

Kenyelletso ea ho sila ea APMT e nang le moralo o matla oa geometry e thusa ho sebetsana le tšepe ea tšepe.

LBH:

Lisebelisoa li entsoe ka eng?

Hoo e batlang e le lisebelisoa tsohle li na le carbide e entsoeng ka samente, e hlahisoang ke motsoako oa tungsten carbide (WC) le cobalt (Co). Likaroloana tse thata ka har'a seketsoana ke WC, athe Co e ka nkoa e le sekhomaretsi se ts'oereng sephutheloana hammoho.

Ho sila mahetla ke eng?

Ho sila ka mahetla ho hlahisa lifahleho tse peli ka nako e le 'ngoe, tse hlokang ho siloa ha peripheral hammoho le ho sila sefahleho. Ho sila ka mahetla ho ka etsoa ke batho ba setso ba sehang mahetleng a lisekoere, hape ka ho sebelisa li-cut cutters, li-cutters tse bolelele bo bolelele le li-cutters tsa mahlakoreng le sefahleho.