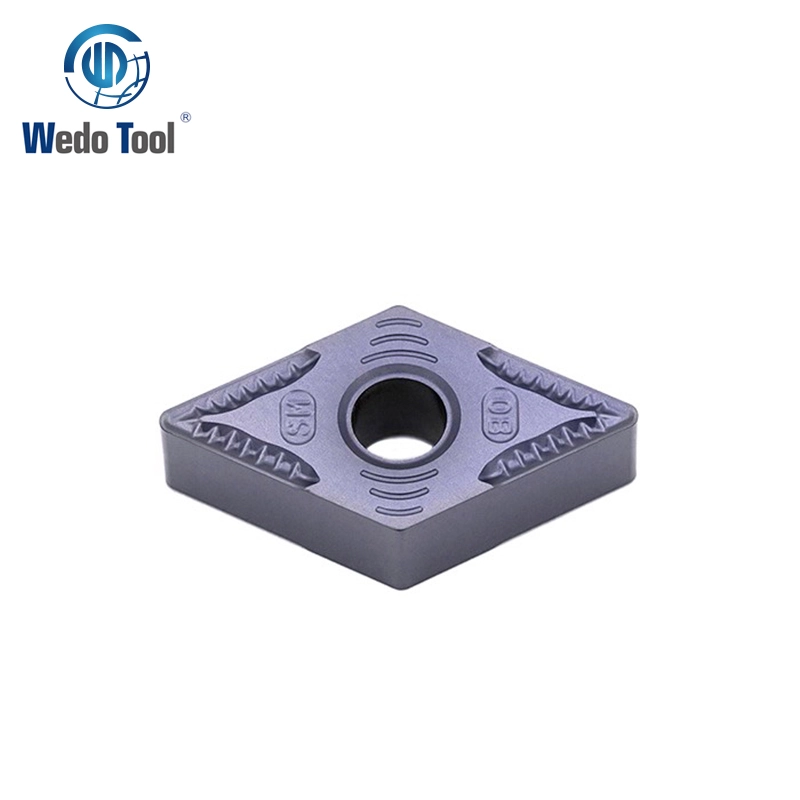

- Product name: LOGU Inserts

- Series: LOGU

- Chip-Breakers: GM/MM

description

Product Information:

LOGU is indexable cutter used for High Feed Rate cut, it includes a double-sided indexable insert and 4 cutting edges. The convex cutting edge version of the insert ensures gentle entry of the cutting edge into the material. 4 unique insert designs offer a variety of machining options。

Specifications:

Type | Ap (mm) | Fn (mm/rev) | CVD | PVD | |||||||||

WD3020 | WD3040 | WD1025 | WD1325 | WD1525 | WD1328 | WR1010 | WR1520 | WR1525 | WR1028 | WR1330 | |||

LOGU030310ER-GM | Apmax=1 | 0.50-1.50 | ● | ● | O | O | |||||||

● : Recommended Grade

O: Optional Grade

Application:

Solid carbide provides better rigidity than high speed steel. It is extremely heat-resistant and used for high-speed applications on cast iron, non-ferrous materials, plastics and other tough-to-machine materials.

FAQ:

What are face mills?

Face milling is a machining process in which the milling cutting is placed perpendicular to the workpiece. The milling cutting is essentially positioned “face down” towards the top of the workpiece. When engaged, the top of the milling cutting grinds away at the top of the workpiece to remove some of its material.

What is the difference between face milling and End Milling?

These are two of the most prevalent milling operations, each using different types of cutters – the and mill and the face mill. The difference between End Milling and face milling is that an End Mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting.