why is carbide insert ?

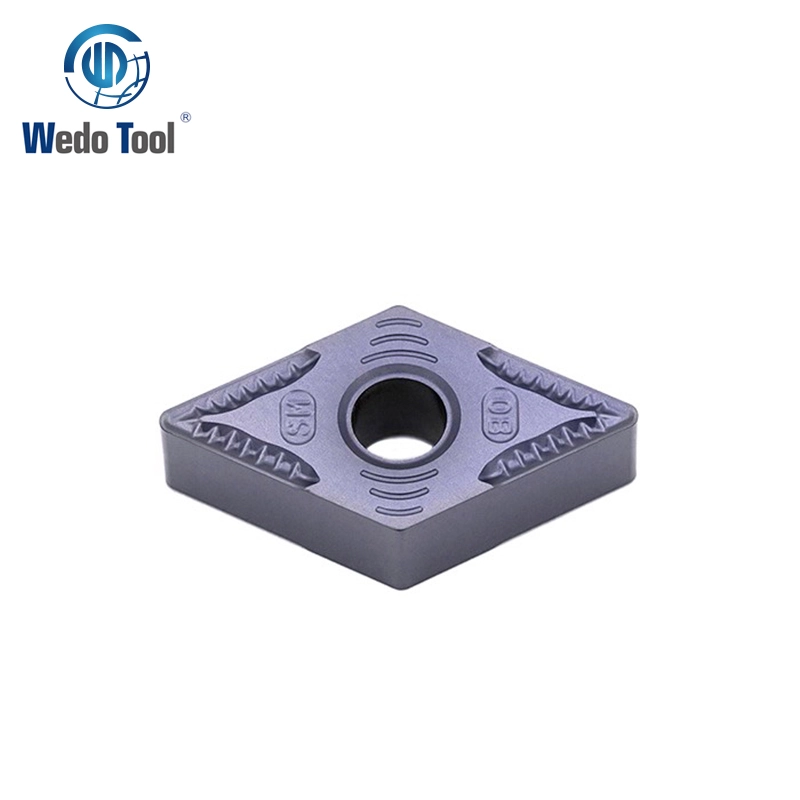

CNC carbide inserts have a broader class used of high-speed machining, this insert material is through the production of powder metallurgy, composed of hard carbide granules and the quality of a material soft metal bond, at present, there are hundreds of different composition of WC cemented carbide, most of them are used as binder, cobalt chromium and nickel is also commonly used binder elements, Other alloying elements can also be added.

The selection of CNC carbide inserts: the turning is the main process of cemented carbide processing technology, especially in the heavy machinery manufacturing industry, the choice of cutting tool is particularly important. According to the different processing equipment, compared with ordinary processing, heavy turning has the characteristics of large cutting depth, low cutting speed, slow feed speed, machining allowance up to 35-50mm side, in addition, due to poor balance of the workpiece, machining allowance distribution is not uniform, machine tool parts imbalance and other factors caused by vibration, The dynamic balancing process consumes a lot of maneuvering time and auxiliary time. Because of this, to processing heavy parts, improve the productivity or efficiency of mechanical equipment, must be from the increased thickness of cutting layer and feed, we should pay attention to the cutting parameters and the choice of blade, improve the structure and shape of the blade, considering the strength characteristics of blade material, thereby increasing cutting parameters, cutting significantly reduce maneuver time.

Commonly used inserts materials are high speed steel, carbide, ceramics, etc., large cutting depth can generally reach 30-50mm, allowance is not uniform, the workpiece surface has hardened layer, in the rough processing stage blade wear mainly in the form of abrasive wear: cutting speed is generally 15-20m/ minute, although the speed value is in the chip where the bump, Cutting the high temperature between the chip contact point and the front knife surface in the liquid state, reduce friction, inhibit a generation of chip bump, blade material should be wear-resistant, impact resistance, ceramic blade hardness is high, but the bending strength is low, impact toughness is low, not suitable for large turning, allowance is not uniform. And carbide has "high wear resistance, high bending strength, good impact toughness and high hardness" and a series of advantages, and cemented carbide with low coefficient of friction, can reduce the cutting force and cutting temperature, greatly improving the durability of blade, suitable for high hardness materials and heavy turning rough machining, is the ideal choice of the cutting blade material.

Improve carbide numerical control the turning speed of heavy machinery blades is to improve the production efficiency, shorten the production cycle is one of the key factors, in this process, a large number of surplus was cut into several pen, the depth of each are tiny, using the cutting performance of cemented carbide nc blades, can greatly improve the cutting speed, thereby improving the production efficiency, prolong service life, Reduce costs and profits.

Wedo CuttingTools Co,.Ltd is well-known as one of the leading carbide inserts suppliers in China, specialized in providing high quality products with competitive price.