Advantages of CVD Coated Carbide Inserts

After CVD process for diamond-coated tools, the hardness of complex-shaped tools is similar to the natural diamond, ant the wear rate of the blade tip is similar to burnt diamond too. This is usually used for copper alloys and aluminum copper alloys, GFRP, Zinc, pre-fired ceramics and other materials cutting. When machining aluminum alloys with CVD tools, the life is 5~10 times than common cemented carbide; when machining high-content silicon aluminum alloys, it is 10 ~ 50 times longer. When processing pre-fired ceramic pairs, it is up to 100 ~1000 times.

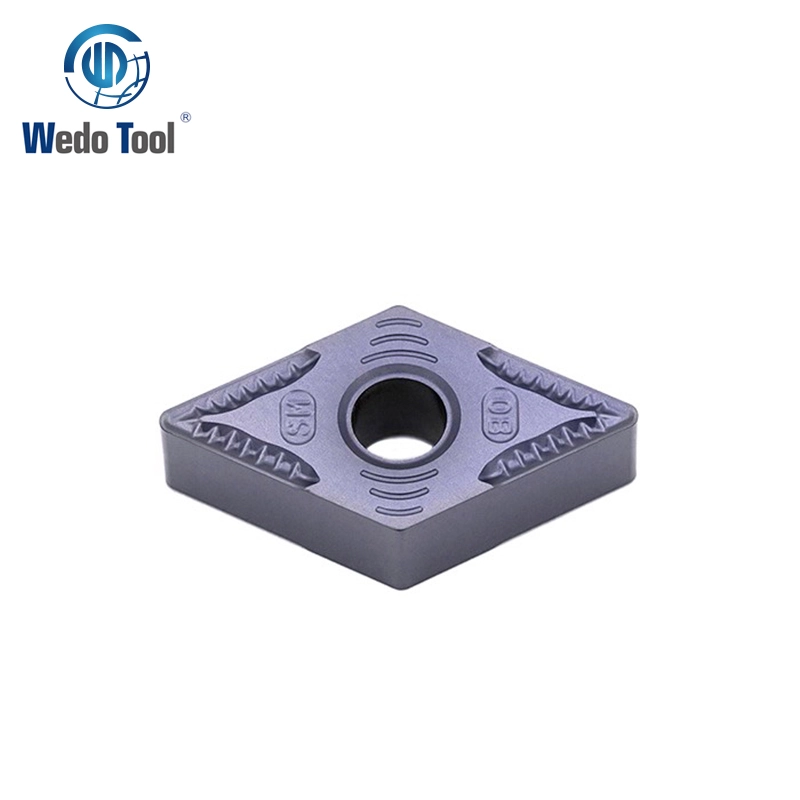

At present, Wedo cutting tools Co,Ltd can provide CVD Coated Carbide cutting tools: Turning inserts, Milling inserts, Drilling inserts.

Wedo CuttingTools Co,.Ltd is well-known as one of the leading carbide inserts suppliers in China, specialized in providing high quality products with competitive price.