incazelo

Ulwazi Lomkhiqizo:

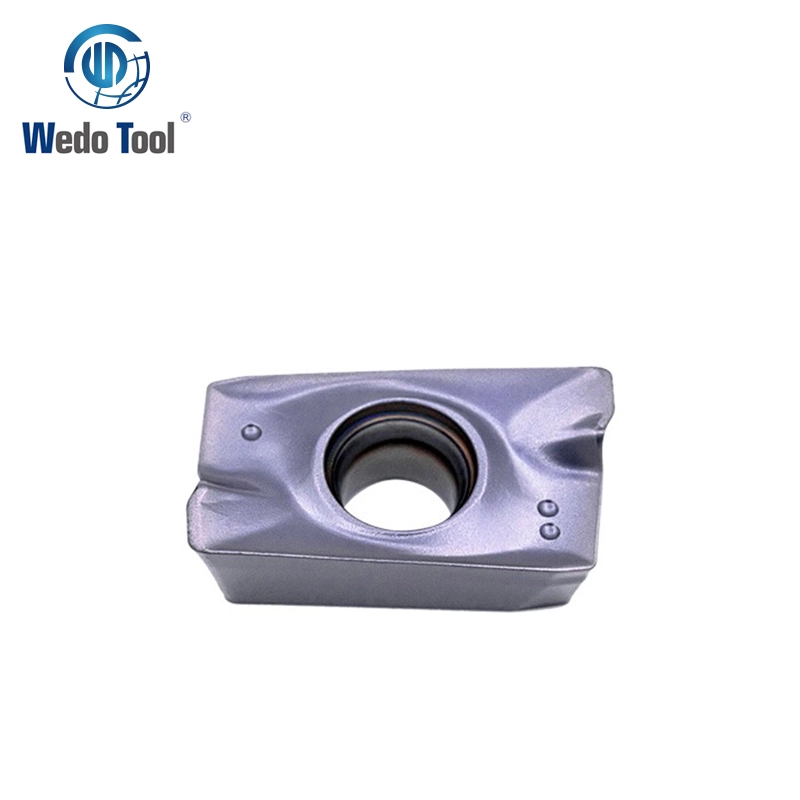

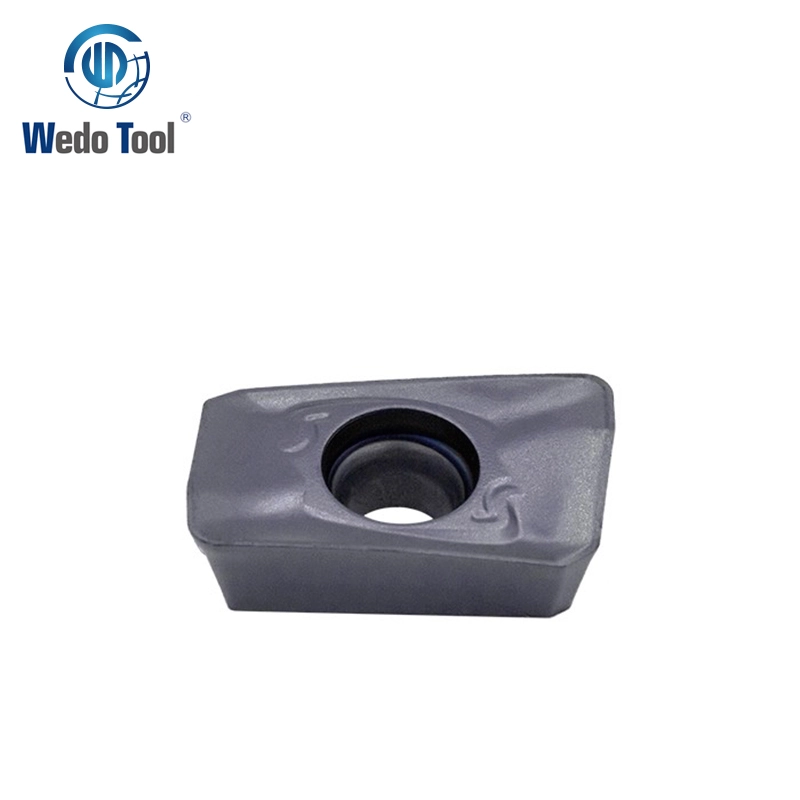

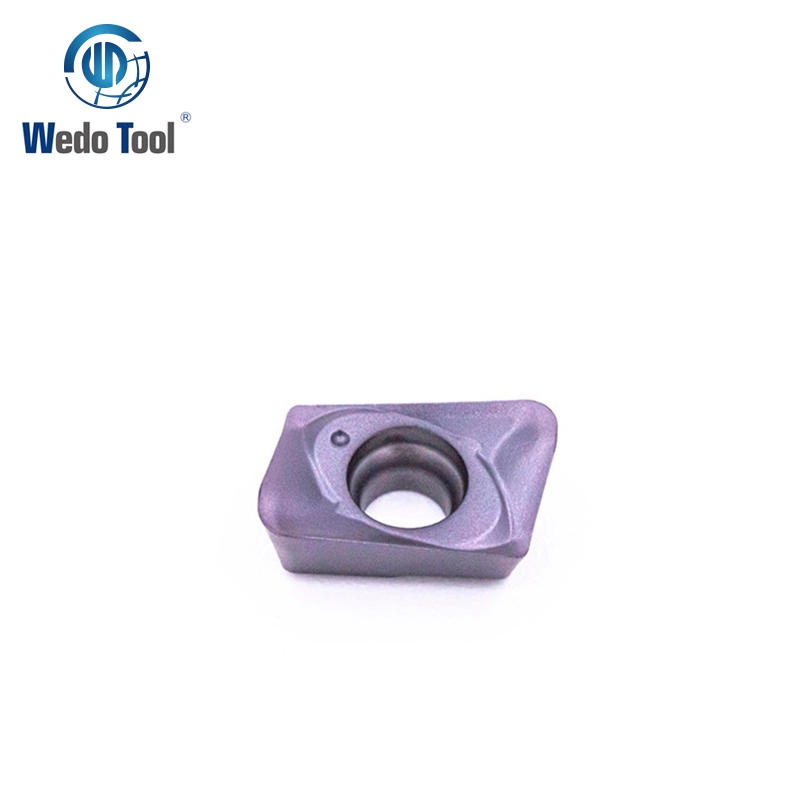

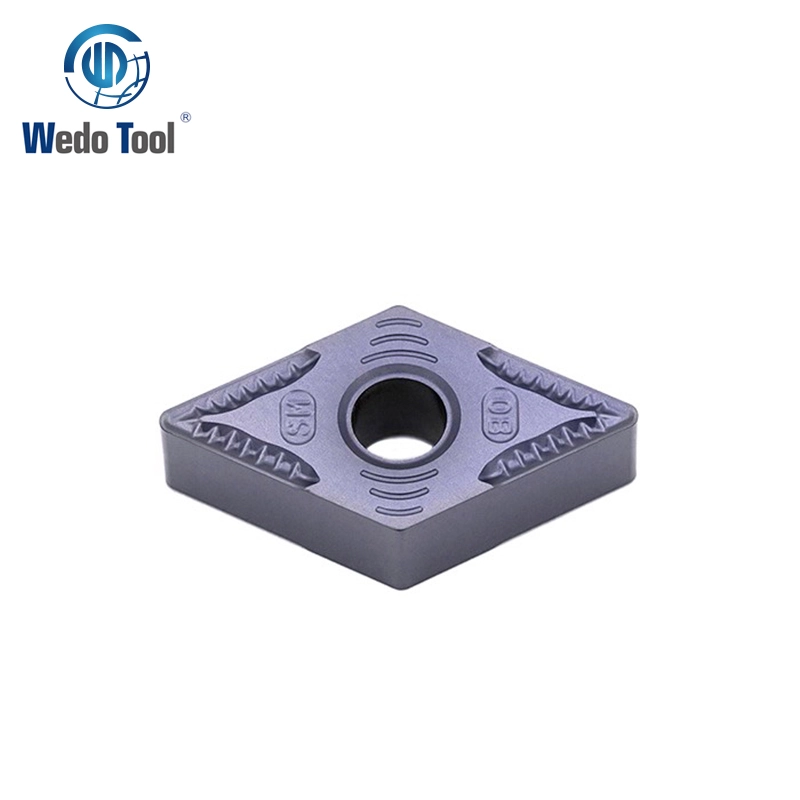

I-Carbide APMT PVD Coated inserts ivamise ukusetshenziselwa izinqamuli zokugaya eziyisikwele zamahlombe kanye nezisiki zokugaya ubuso. Okufakiwe kwe-APMT kune-IC. Banomkhawulo wokusika obukhali futhi ocijile kanye ne-engeli yokusiza engu-11°. Anezimbobo zesikulufa ezidalwe ngokuhambisana ne-ISO. Ngokuvamile, ibhekwa njenge-2 imiphetho yokusika. Nokho, empeleni banamaphethelo angu-4 okusika. uma efakwe kuma-milling cutters angu-90° futhi womabili amaphethelo aba buthuntu, angafakwa kuma-milling cutters angu-75° Â futhi aqhubeke nezinye izinhlelo zokusebenza zokugaya nezinye iziphetho ezimbili.I-APMT izoba yinketho enhle kubasebenzisi bokugcina, ngoba ingathuthukisa kakhulu ukukhiqiza.

Imininingwane:

Uhlobo | Ap (mm) | Fn (mm/rev) | I-CVD | I-PVD | |||||||||

WD3020 | WD3040 | WD1025 | WD1325 | WD1525 | WD1328 | WR1010 | WR1520 | WR1525 | WR1028 | WR1330 | |||

APMT1135PDER-XR | 2.50-7.50 | 0.05-0.25 | • | • | O | O | |||||||

APMT1605PDER-XR | 3.50-10.00 | 0.07-0.50 | • | • | O | O | |||||||

APMT1135PDER-M2 | 2.50-7.50 | 0.05-0.25 | • | • | O | O | |||||||

APMT160408PDER-M2 | 3.50-10.00 | 0.07-0.30 | • | • | O | O | |||||||

APMT1135PDER-GM | 2.50- 7.50 | 0.05-0.25 | • | • | O | O | |||||||

APMT160408PDER-GM | 3.50-10.00 | 0.07-0.50 | • | • | O | O | |||||||

APMT1135PDER-H2 | 2.50-7.50 | 0.05-0.25 | • | • | O | O | |||||||

APMT160408PDER-H2 | 3.50-10.00 | 0.07-0.30 | • | • | O | O | |||||||

• : Ibanga Elinconyiwe

O: Ibanga Lokuzikhethela

Isicelo:

Ukufakwa kokugaya kwe-APMT okunomklamo oqinile wejiyomethri kuvumela ukubhekana nensimbi ye-steel.alloy, insimbi engagqwali, ne-cast iron.

I-FAQ:

Kwenziwa ngani okokufaka?

Cishe zonke izinto ezifakiwe zihlanganisa i-carbide enosimende, ewumphumela wenhlanganisela ye-tungsten carbide (WC) ne-cobalt (Co). Izinhlayiya ezinzima ngaphakathi kokufakwayo ziyi-WC, kuyilapho i-Co ingacatshangwa njengeglue ebamba okufakiwe ndawonye.

Kuyini ukugaya ihlombe?

Ukugaya amahlombe kukhiqiza ubuso obubili ngesikhathi esisodwa, okudinga ukugaywa kwe-peripheral kuhlanganiswe nokugaya ubuso. Ukugaywa kwamahlombe kungenziwa ngabasiki bendabuko besikwele bamahlombe, futhi ngokusebenzisa izinqamuleli zokugaya, izisiki ezisemaphethelweni amade kanye nezisiki zokugaya eziseceleni nezobuso.