Inkcazo

Ulwazi ngeMveliso:

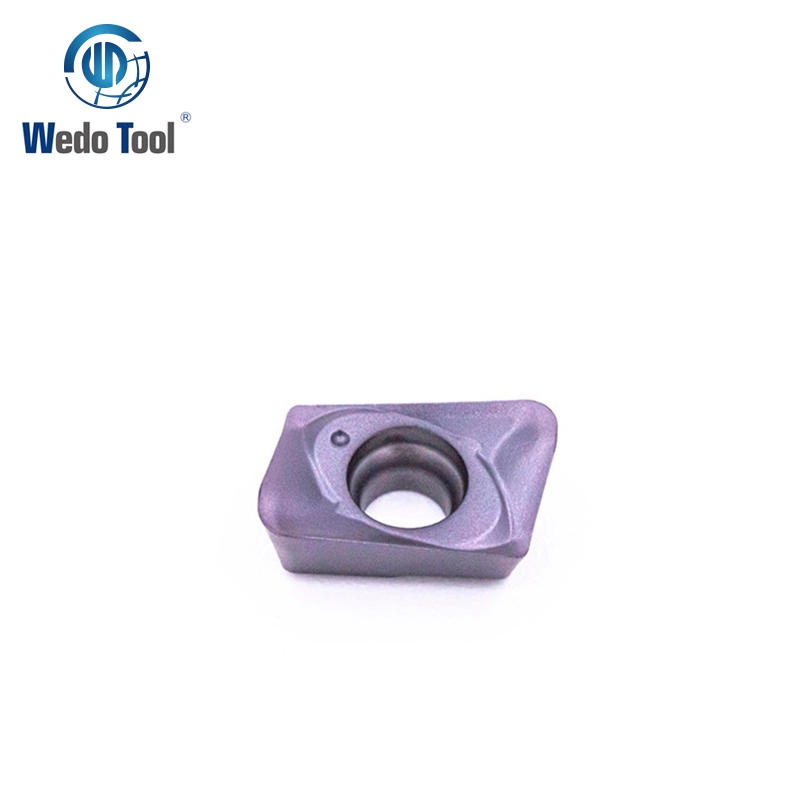

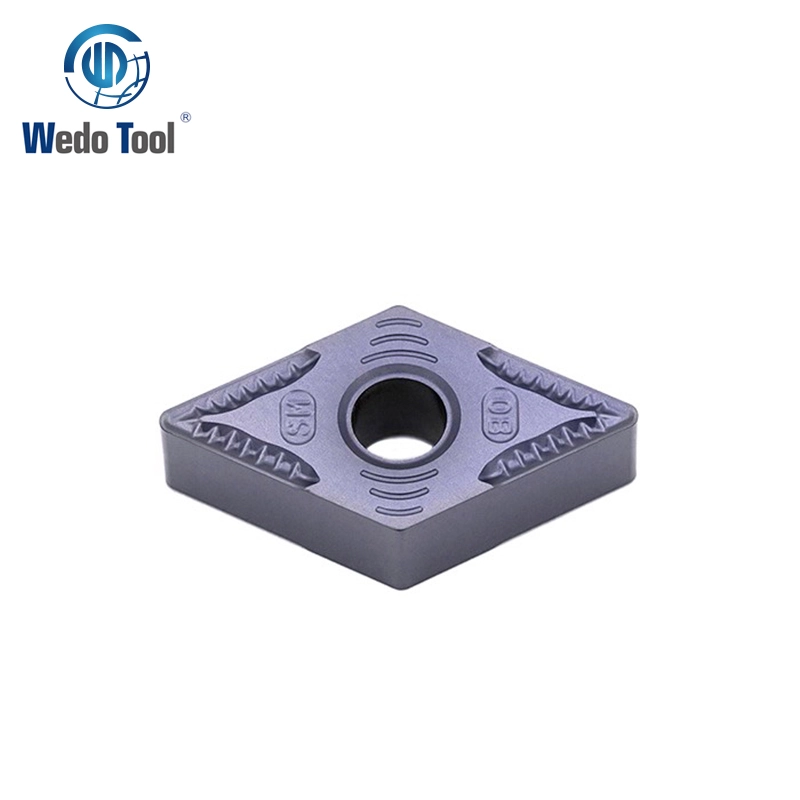

I-90 ° I-Shoulder Milling Insert enemiphetho emithathu yokusika iphezulu kakhulu i-helical cut edge edge yokufaka. I-90 ° yokusila egxalabeni kunye nomatshini ogudileyo kwaye othambileyo ubonelela ngemveliso ephezulu ngenani eliphezulu lamazinyo. Umzimba wesixhobo esomeleleyo kunye nobukhulu obukhulu obungundoqo, Iintlobo ezahlukeneyo zejometri.

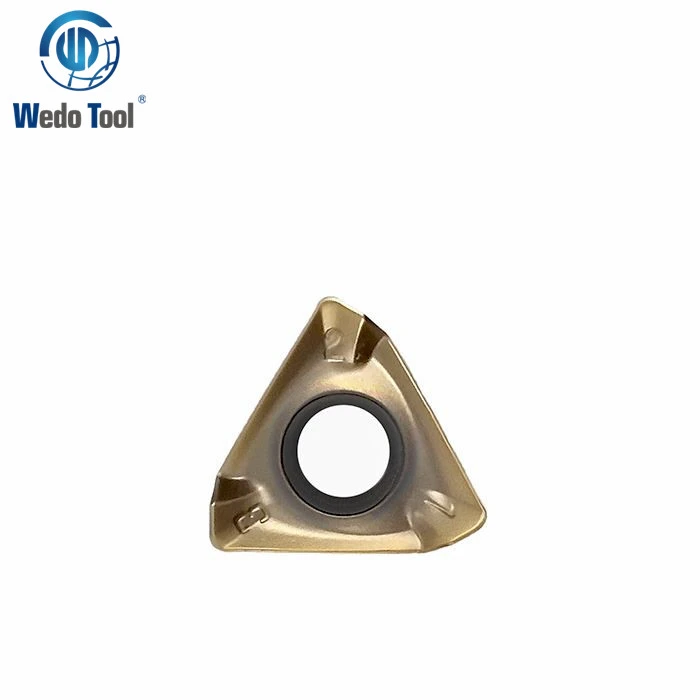

I-TPKT i-carbide eqhelekileyo (ene-coating) ifakela i-milling imiphetho eqinile, enika ukuthembeka okuphezulu kunye nokunyamezela ixesha elide.

T - imilo engunxantathu yofakelo lokusila

P - Faka ngokucokisekileyo phantsi komphetho oyintloko wokusika (11 °).

K- Ukunyamezela kunye nemilinganiselo ye-carbide

T - Umngxuma ngokufaka kunye ne-single sided chip breaker.

Iinkcukacha:

Uhlobo | Ap (mm) | Fn (mm/rev) | CVD | PVD | |||||||||

WD 3020 | WD 3040 | WD 1025 | WD 1325 | WD 1525 | WD 1328 | WR 1010 | WR 1520 | WR 1525 | WR 1028 | WR 1330 | |||

TPKT040202R-M | 0.50-3.00 | 0.04-0.08 | ● | ● | O | O | |||||||

TPKT040204R-M | 0.50-3.00 | 0.04-0.08 | ● | ● | O | O | |||||||

TPKT060302R-M | 1.00-4.00 | 0.04-0.10 | ● | ● | O | O | |||||||

TPKT060304R-M | 1.00-4.00 | 0.04-0.10 | ● | ● | O | O | |||||||

TPKT060308R-M | 1.00-4.00 | 0.04-0.10 | ● | ● | O | O | |||||||

TPKT100404R-M | 2.00-6.00 | 0.05-0.12 | ● | ● | O | O | |||||||

TPKT100408R-M | 2.00-6.00 | 0.05-0.12 | ● | ● | O | O | |||||||

TPKT100416R-M | 2.00-6.00 | 0.05-0.12 | ● | ● | O | O | |||||||

TPKT150508R-M | 3.00-9.00 | 0.07-0.17 | ● | ● | O | O | |||||||

TPKT150516R-M | 3.00-9.00 | 0.07-0.17 | ● | ● | O | O | |||||||

TPKT150524R-M | 3.00-12.00 | 0.07-0.17 | ● | ● | O | O | |||||||

TPKT190608R-M | 4.50-12.00 | 0.09-0.22 | ● | ● | O | O | |||||||

TPKT190616R-M | 4.50-12.00 | 0.09-0.22 | ● | ● | O | O | |||||||

TPKT190624R-M | 4.50-12.00 | 0.09-0.22 | ● | ● | O | O | |||||||

TPKT190632R-M | 4.50-12.00 | 0.09-0.22 | ● | ● | O | O | |||||||

●: IBanga elicetyiswayo

O: IBanga lokuzikhethela

Usetyenziso:

Ukwenziwa komatshini jikelele, insimbi engenasici kunye nokukhanya okubukhali okubukhali, intsimbi kunye nezixhobo ezingenayo i-ferrous, i-chip splitter insert.Isetyenziswa ngokubanzi kwisicelo sokukhanya okuphakathi & kwi-machining steel stainsless.

FAQ:

Yintoni ukugaya amagxa?

Ukungqusha kwamagxa kuvelisa ubuso obubini ngaxeshanye, nto leyo ifuna ukungqusha ngeperipheral kudityaniswe nokungqusha ubuso. Ukusila amagxa kunokwenziwa ngabasiki bemveli abasikweri bamagxa, kwaye kwakhona ngokusebenzisa abasiki besiphelo, abasiki becala elide kunye nabasiki becala kunye nobuso.

Yeyiphi indlela yokusila ekhuthazwa ngokubanzi?

Ukusila phantsi kuyacetyiswa ngokubanzi. Ngendlela yokusila ephantsi, isiphumo sokutshisa sinokuthintelwa, sikhokelela kubushushu obuncinci kunye nobuncinci bomsebenzi wokuqina.

Wedo CuttingTools Co,.Ltdwaziwa njengomnye wabaphambiliukufakwa kwe-carbideababoneleli eTshayina.Iimveliso eziphambili zenkampani ziukuguqula ukufakwa,Ukufakwa kokugaya,Drilling ufakelo, ukufaka imisonto, ukufakwa kwigrooving kunyeisiphelo sokugaya.