inkcazelo

Product Information:

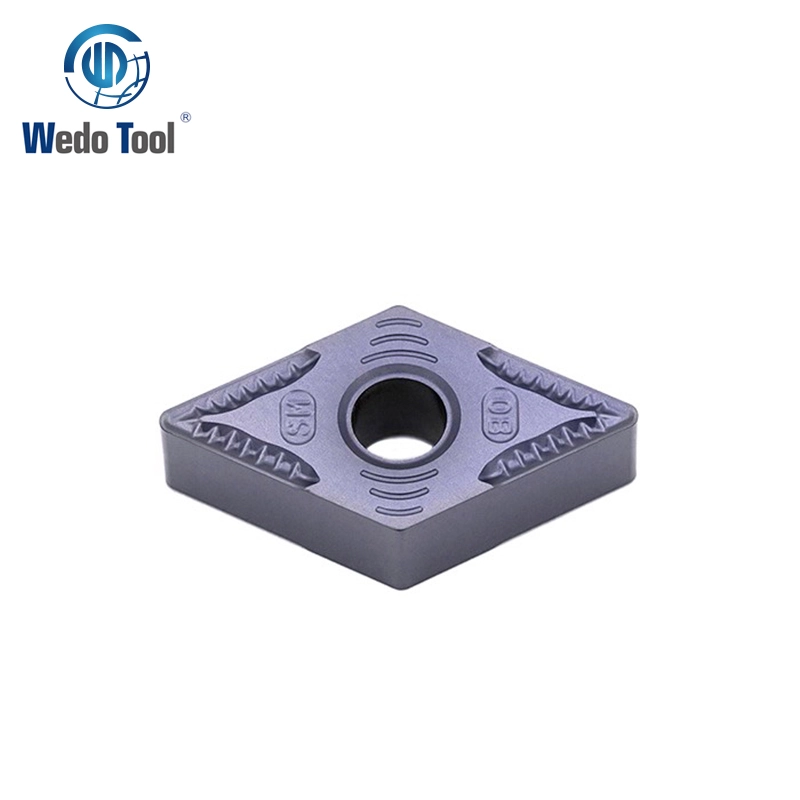

APKT milling insert is quadrilateral shape with the clearance under main cutting edge. Its has hole through and single sided chip breaker.

The 3D helical cutting edge can reduce the cutting force. As most face milling, shoulder milling cutters are using indexable inserts with wedge type clamping or screw-on type clamping to achieve high-quality machining. Our APKT inserts will be your premium choice for helical milling.

Specifications:

Type | Ap (mm) | Fn (mm/rev) | CVD | PVD | |||||||||

WD 3020 | WD 3040 | WD 1025 | WD 1325 | WD 1525 | WD 1328 | WR 1010 | WR 1520 | WR 1525 | WR 1028 | WR 1330 | |||

APKT150412-PM | 1.2-8 | 0.08-0.2 | ● | ● | O | O | |||||||

APKT150415-KM | 1.2-8 | 0.08-0.2 | ● | ● | O | O | |||||||

● : Recommended Grade

O: Optional Grade

Application

The type of carbide grade and the coating on inserts is originally intended for milling stainless steel, but it also performs when milling other alloys.

FAQ:

What is helical milling?

Helical milling is a hole-making process in which the milling tool proceeds a helical path while rotates around its own axis, presenting several advantages in relation to conventional drilling. The helical path can be decomposed into axial and tangential directions, combining frontal and peripheral cutting.

What is carbide insert use for?

Carbide inserts are replaceable with a huge variety of styles, sizes and grades.they are used to machine different kinds of metals, including steels, carbon, cast iron, high-temperature alloys and other non-ferrous metals.

Wedo CuttingTools Co,.Ltd is well-known as one of the leading carbide inserts suppliers in China. The company’s main products are turning inserts, Milling inserts, Drilling inserts, threading inserts, grooving inserts and End Mill.