Opis

Product Information:

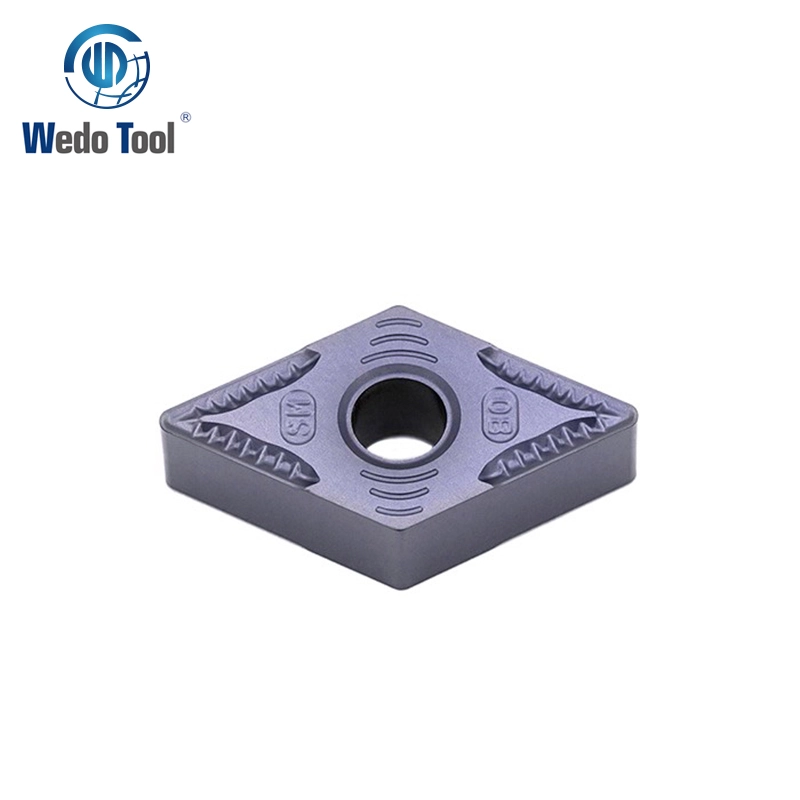

WNMG Turning Inserts with negative (0°) relief angle, have strong edge. The general applications and varying depths of cut dependent on chip breaker type across most materials. WNMG Turning Inserts can deal with multiple operations by combining different chip breakers and grades.it’s a very good economical choice for your production, since they are made symmetrically, so that when the one cutting edge is worn they can rotate to another edge.

Specifications:

Application | Type | Ap (mm) | Fn (mm/rev) | Grade | |||||||||||

CVD | PVD | ||||||||||||||

WD 4215 | WD 4315 | WD 4225 | WD 4325 | WD 4235 | WD 4335 | WD 1025 | WD 1325 | WD 1525 | WD 1328 | WR 1010 | WR 1325 | ||||

P Semi Finishing | WNMG080404-AM | 0.60-4.30 | 0.10-0.30 | ● | O | ● | O | O | |||||||

WNMG080408-AM | 1.20-4.30 | 0.20-0.60 | ● | O | ● | O | O | ||||||||

WNMG080412-AM | 1.80-4.30 | 0.30-0.90 | ● | O | ● | O | O | ||||||||

WNMG080416-AM | 2.40-4.30 | 0.40-1.20 | ● | O | ● | O | O | ||||||||

● : Recommended Grade

O: Optional Grade

Application | Type | Ap (mm) | Fn (mm/rev) | Grade | |||||||||||

CVD | PVD | ||||||||||||||

WD 4215 | WD 4215 | WD 4225 | WD 4325 | WD 4235 | WD 4335 | WD 1025 | WD 1325 | WD 1525 | WD 1328 | WR 1010 | WR 1325 | ||||

P Rough Machining | WNMG060408-AR | 0.80-4.00 | 0.15-0.50 | ● | O | ||||||||||

WNMG060412-AR | 0.80-4.00 | 0.15-0.50 | ● | O | |||||||||||

WNMG080408-AR | 0.80-4.50 | 0.15-0.55 | ● | O | |||||||||||

WNMG080412-AR | 0.80-4.50 | 0.20-0.55 | ● | O | |||||||||||

● : Recommended Grade

O: Optional Grade

Application | Type | Ap (mm) | Fn (mm/rev) | Grade | |||||||||||

CVD | PVD | ||||||||||||||

WD 4215 | WD 4315 | WD 4225 | WD 4325 | WD 1025 | WD 1325 | WD 1525 | WD 1328 | WR 1010 | WR 1325 | WR 1525 | WR 1330 | ||||

M Finishing | WNMG060404-BF | 0.25-2.40 | 0.05-0.15 | ● | ● | O | O | ||||||||

WNMG060408-BF | 0.50-2.40 | 0.10-0.30 | ● | ● | O | O | |||||||||

WNMG080404-BF | 0.25-3.20 | 0.05-0.15 | ● | ● | O | O | |||||||||

WNMG080408-BF | 0.50-3.20 | 0.10-0.30 | ● | ● | O | O | |||||||||

WNMG080412-BF | 0.75-3.20 | 0.15-0.45 | ● | ● | O | O | |||||||||

WNMG080416-BF | 1.05-3.20 | 0.20-0.60 | ● | ● | O | O | |||||||||

● : Recommended Grade

O: Optional Grade

Application | Type | Ap (mm) | Fn (mm/rev) | Grade | |||||||||||

CVD | PVD | ||||||||||||||

WD 4215 | WD 4315 | WD 4225 | WD 4325 | WD 1025 | WD 1325 | WD 1525 | WD 1328 | WR 1010 | WR 1325 | WR 1525 | WR 1330 | ||||

M Semi Finishing | WNMG060404-BM | 0.30-2.10 | 0.10-0.30 | O | O | ● | O | O | |||||||

WNMG060408-BM | 0.65-2.10 | 0.15-0.45 | O | O | ● | O | O | ||||||||

WNMG080404-BM | 0.30-2.90 | 0.10-0.30 | O | O | ● | O | O | ||||||||

WNMG080408-BM | 0.65-2.90 | 0.15-0.45 | O | O | ● | O | O | ||||||||

WNMG080412-BM | 0.95-2.90 | 0.20-0.60 | O | O | ● | O | O | ||||||||

WNMG080416-BM | 1.25-2.90 | 0.25-0.75 | O | O | ● | O | O | ||||||||

●: Recommended Grade

O: Optional Grade

Application | Type | Ap (mm) | Fn (mm/rev) | Grade | |||||||||||

CVD | PVD | ||||||||||||||

WD 4215 | WD 4315 | WD 4225 | WD 4325 | WD 1025 | WD 1325 | WD 1525 | WD 1328 | WR 1010 | WR 1325 | WR 1528 | WR 1330 | ||||

M Rough Machining | WNMG060404-BR | 0.30-2.10 | 0.10-0.30 | O | O | O | ● | ● | O | ||||||

WNMG060408-BR | 0.65-2.10 | 0.15-0.45 | O | O | O | ● | ● | O | |||||||

WNMG080404-BR | 0.30-2.90 | 0.10-0.30 | O | O | O | ● | ● | O | |||||||

WNMG080408-BR | 0.65-2.90 | 0.15-0.45 | O | O | O | ● | ● | O | |||||||

WNMG080412-BR | 0.95-2.90 | 0.20-0.60 | O | O | O | ● | ● | O | |||||||

WNMG080416-BR | 1.25-2.90 | 0.25-0.75 | O | O | O | ● | ● | O | |||||||

● : Recommended Grade

O: Optional Grade

Application | Type | Ap (mm) | Fn (mm/rev) | Grade | |||

CVD | |||||||

WD3020 | WD3040 | WD3315 | WD3415 | ||||

K Semi Finishing | WNMG080404-CM | 0.08-0.25 | 0.40-2.90 | ● | ● | ||

WNMG080408-CM | 0.15-0.45 | 0.80-2.90 | ● | ● | |||

WNMG080412-CM | 0.25-0.66 | 1.20-2.90 | ● | ● | |||

• : Recommended Grade

O: Optional Grade

Application | Type | Ap (mm) | Fn (mm/rev) | Grade | ||||||||||||

CVD | PVD | |||||||||||||||

WD 4215 | WD 4315 | WD 4225 | WD 4325 | WD 1025 | WD 1325 | WD 1525 | WD 1328 | WR 1010 | WR 1520 | WR 1525 | WR 1028 | WR 1330 | ||||

S Semi Finishing | WNMG080404-DM | 0.40-4.30 | 0.08-0.25 | O | O | O | ● | ● | O | O | ||||||

WNMG080408-DM | 0.80-4.30 | 0.15-0.45 | O | O | O | ● | ● | O | O | |||||||

WNMG080412-DM | 1.20-4.30 | 0.25-0.66 | O | O | O | ● | ● | O | O | |||||||

WNMG080416-DM | 1.60-4.30 | 0.30-0.90 | O | O | O | ● | ● | O | O | |||||||

● : Recommended Grade

O: Optional Grade

Application:

These WNMG Turning Inserts can deal with multiple operations by combining different chip breakers and grades. Recommended for rough, semi-finishing and finishing of machining most steels, stainless steels, cast irons and super alloys under stable conditions.

FAQ:

What is the difference between negative and positive inserts?

The difference between Negative and Positive insert lies in they with different clearance angle. The positive inserts have clearance angle between 1 degree to 90 degree. The clearance angle of negative insert is o degree .

Which insert type is the best choice for rough machining?

When you need roughing and general turning .the negative inserts are the first and best option. negative insert allows deeper depths and higher feed rates due to strong insert shapes and thickness.

Hot Tags: WNMG insert, turning, milling, cutting, grooving, factory, wnmg 0804, wnmg insert angle, wnmg 080404, wnmg06