description

Product Information:

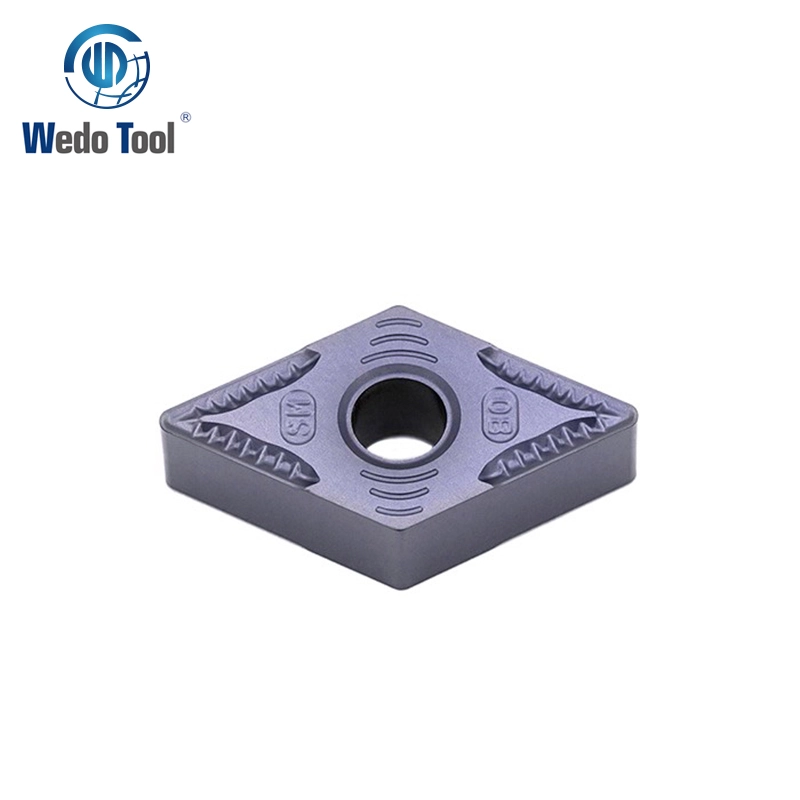

Cost-efficiency with Process Reliability Tungsten carbide Milling inserts HNMG. face milling insert.it’s double-sided 12-edge economical face milling cutter with its own wiper blade and cutting edge has a certain strength with PVD Coating, which offers excellent wear and oxidation resistance, good chipping resistance.Dimensionally accurate, durable and reliable performance.

Specifications:

Type | Ap (mm) | Fn (mm/rev) | CVD | PVD | |||||||||

WD3020 | WD3040 | WD1025 | WD1325 | WD1525 | WD1328 | WR1010 | WR1520 | WR1525 | WR1028 | WR1330 | |||

HNMG0907ANSN-R | 1.50-4.00 | 0.20-0.70 | • | • | O | O | |||||||

HNMG0907ANSN-M | 1.00-3.00 | 0.05-0.15 | • | • | O | O | |||||||

• : Recommended Grade

O: Optional Grade

Application:

This kind of insert can obtain a good surface finishing, high economy, suitable for machining material steel, stainless steel, cast iron and super alloys.

FAQ:

What is chip breaker?

Chip breaker is a shoulder in a machine tool.it is made by grinding a groove parallel.in order to cut the edge or by attaching a plate to the top to form a wall against which the chip produced in turning or other machining will be broken up.

What are coated carbides?

Coated cemented carbide means the cemented carbide with a coating. It contains PVD and CVD coating. Coated carbide with high bond strength and extreme wear resistance.It’s the first choice for a wide variety of tools and applications.