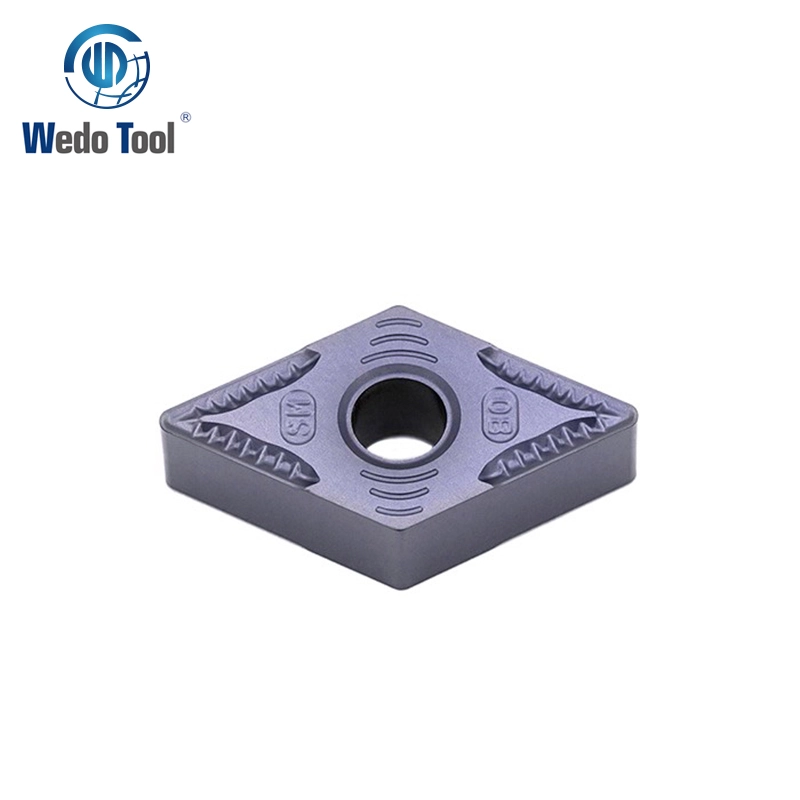

- Product name: SEER Inserts

- Series: SEER

- Chip-Breakers: GM

description

Product Information:

Face milling produces flat surfaces and machines work to the required length. In face milling, the feed can be either horizontal or vertical. Single-sided milling insert SEER insert. An insert for face milling cutters. For face milling.Flat surface clamping interface 90 degree included angle 45 degree cutting edge angle.

Specifications:

Type | Ap (mm) | Fn (mm/rev) | CVD | PVD | |||||||||

WD3020 | WD3040 | WD1025 | WD1325 | WD1525 | WD1328 | WR1010 | WR1520 | WR1525 | WR1028 | WR1330 | |||

SEER1203-GM | 1.50-6.00 | 0.10-0.25 | ● | ● | O | O | |||||||

SEER1504-GM | 1.50-8.00 | 0.10-0.25 | ● | ● | O | O | |||||||

● : Recommended Grade

O: Optional Grade

Application:

Application for machining steel.stainless steel and cast iron.

FAQ:

What milling method is generally recommended?

Down milling is generally recommended. With the down milling method, the burnishing effect can be avoided, resulting in less heat & minimal work-hardening tendency.

How is milling done?

The milling process is removing the materials by performing many separate and small cuts. It is accomplished by using a cutter with many teeth, spinning the cutter at a high speed, or advancing the material through the cutter slowly.

What are face mills?

Face milling is a machining process in which the milling cutting is placed perpendicular to the workpiece. The milling cutting is essentially positioned “face down” towards the top of the workpiece. When engaged, the top of the milling cutting grinds away at the top of the workpiece to remove some of its material.

Hot Tags: semt insert, turning, milling, cutting, grooving, factory, CNC