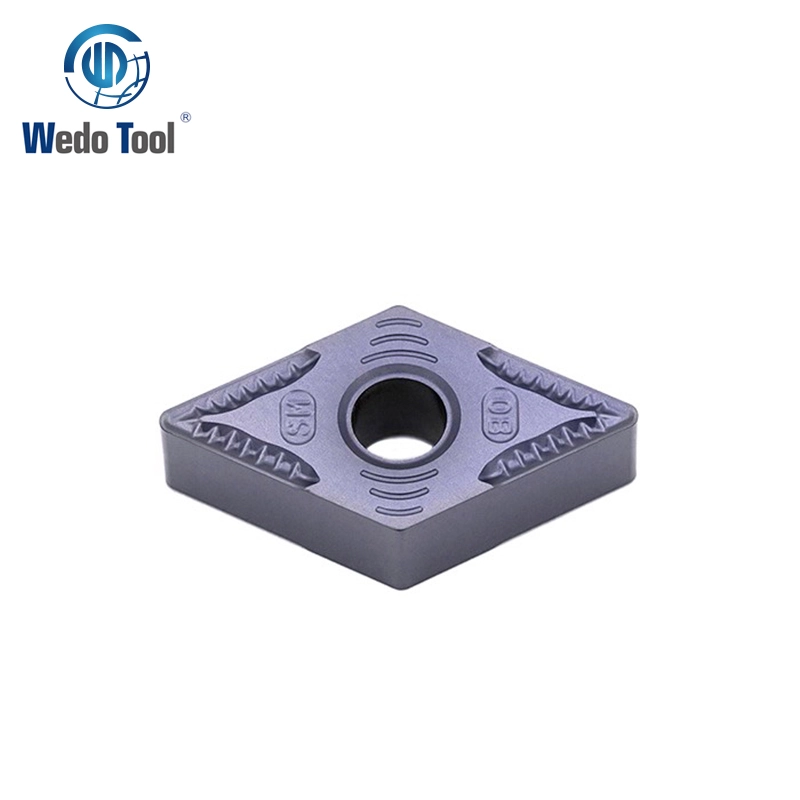

- Isem tal-prodott: daħħal TNMG

- Serje: TNMG

- Chip-Breakers: AM/AR/BF/BM/CM/BR

deskrizzjoni

Informazzjoni dwar il-Prodott:

TNMG Daħħal huwa forma ta' trijangolu b'toqba,angoli negattivi,b'żewġ naħat.Għal firxa wiesgħa ta 'materjali u kundizzjonijiet tal-magni,biex jiggarantixxu makkinar effiċjenti u stabbiltà għoljagħal semi-roughing u roughing.

Sspeċifikazzjonis:

Applikazzjoni | Tip | Ap (mm) | Fn (mm/rev) | Grad | |||||||||||

CVD | PVD | ||||||||||||||

WD 4215 | WD 4315 | WD 4225 | WD 4325 | WD 4235 | WD 4335 | WD 1025 | WD 1325 | WD 1525 | WD 1328 | WR 1010 | WR 1325 | ||||

P Semi Finishing | TNMG160404-AM | 0.60-5.80 | 0.10-0.30 | ● | O | ● | O | O | |||||||

TNMG160408-AM | 1.20-5.80 | 0.20-0.60 | ● | O | ● | O | O | ||||||||

TNMG160412-AM | 1.80-5.80 | 0.30-0.90 | ● | O | ● | O | O | ||||||||

TNMG220408-AM | 1.20-7.70 | 0.20-0.60 | ● | O | ● | O | O | ||||||||

TNMG220412-AM | 1.80-7.70 | 0.30-0.90 | ● | O | ● | O | O | ||||||||

TNMG220416-AM | 2.40-7.70 | 0.40-1.20 | ● | O | ● | O | O | ||||||||

●: Grad Rakkomandat

O: Grad Fakultattiv

Applikazzjoni | Tip | Ap (mm) | Fn (mm/rev) | Grad | |||||||||||

CVD | PVD | ||||||||||||||

WD 4215 | WD 4315 | WD 4225 | WD 4325 | WD 4235 | WD 4335 | WD 1025 | WD 1325 | WD 1525 | WD 1328 | WR 1010 | WR 1325 | ||||

P Rough Makkinar | TNMG160408-AR | 2.00-5.00 | 0.25-0.65 | ● | O | ||||||||||

TNMG220408-AR | 2.50-7.00 | 0.25-0.65 | ● | O | |||||||||||

TNMG220412-AR | 2.50-7.00 | 0.25-0.65 | ● | O | |||||||||||

●: Grad Rakkomandat

O: Grad Fakultattiv

Applikazzjoni | Tip | Ap (mm) | Fn (mm/rev) | Grad | |||||||||||

CVD | PVD | ||||||||||||||

WD 4215 | WD 4315 | WD 4225 | WD 4325 | WD 1025 | WD 1325 | WD 1525 | WD 1328 | WR 1010 | WR 1325 | WR 1525 | WR 1330 | ||||

M Irfinar | TNMG160404-BF | 0.25-3.10 | 0.05-0.15 | ● | ● | O | O | ||||||||

TNMG160408-BF | 0.50-3.10 | 0.10-0.30 | ● | ● | O | O | |||||||||

TNMG160412-BF | 0.75-3.10 | 0.10-0.30 | ● | ● | O | O | |||||||||

●: Grad Rakkomandat

O: Grad Fakultattiv

Applikazzjoni | Tip | Ap (mm) | Fn (mm/rev) | Grad | |||||||||||

CVD | PVD | ||||||||||||||

WD 4215 | WD 4315 | WD 4225 | WD 4325 | WD 1025 | WD 1325 | WD 1525 | WD 1328 | WR 1010 | WR 1325 | WR 1525 | WR 1330 | ||||

M Semi Finishing | TNMG160404-BM | 0.30-4.10 | 0.08-0.25 | O | O | ● | O | O | |||||||

TNMG160408-BM | 0.65-4.10 | 0.15-0.45 | O | O | ● | O | O | ||||||||

TNMG160412-BM | 0.95-4.10 | 0.25-0.65 | O | O | ● | O | O | ||||||||

TNMG220408-BM | 0.65-4.90 | 0.15-0.45 | O | O | ● | O | O | ||||||||

TNMG220412-BM | 0.95-4.90 | 0.25-0.65 | O | O | ● | O | O | ||||||||

●: Grad Rakkomandat

O: Grad Fakultattiv

Applikazzjoni | Tip | Ap (mm) | Fn (mm/rev) | CVD | |||

WD3020 | WD3040 | WD3315 | WD3415 | ||||

K Semi Finishing | TNMG160404-CM | 0.40-4.10 | 0.08-0.25 | ● | O | ||

TNMG160408-CM | 0.80-4.10 | 0.15-0.45 | ● | O | |||

TNMG160412-CM | 1.20-4.10 | 0.25-0.65 | ● | O | |||

TNMG220412-CM | 1.20-4.90 | 0.25-0.65 | ● | O | |||

●: Grad Rakkomandat

O: Grad Fakultattiv

Applikazzjoni | Tip | Ap (mm) | Fn (mm/rev) | Grad | |||||||||||

CVD | PVD | ||||||||||||||

WD 4215 | WD 4315 | WD 4225 | WD 4325 | WD 1025 | WD 1325 | WD 1525 | WD 1328 | WR 1010 | WR 1325 | WR 1525 | WR 1330 | ||||

M Makkinar mhux maħdum | TNMG160404-BR | 0.30-4.10 | 0.08-0.25 | O | O | ● | O | O | |||||||

TNMG160408-BR | 0.65-4.10 | 0.15-0.45 | O | O | ● | O | O | ||||||||

TNMG160412-BR | 0.95-4.10 | 0.25-0.65 | O | O | ● | O | O | ||||||||

TNMG220408-BR | 0.65-4.90 | 0.15-0.45 | O | O | ● | O | O | ||||||||

TNMG220412-BR | 0.95-4.90 | 0.25-0.65 | O | O | ● | O | O | ||||||||

●: Grad Rakkomandat

O: Grad Fakultattiv

Applikazzjoni:

L-Insert TNMG jintuża prinċipalment fl-oqsma tat-tidwir tal-metall, tħin, qtugħ u grooving, tidwir tal-ħajt, eċċ Applikazzjoni għal materjal tal-azzar.

FAQ:

X'inhu daħħal TNMG?

Daħħal TNMG huwa daħħal ISO tat-tidwir u l-aktar użat komunement fi kważi l-Tornijiet CNC kollha. Jintuża għal applikazzjonijiet ta 'Tidwir tal-Profil u applikazzjonijiet ġenerali ta' tidwir tax-xaft. Daħħal qed ikollu 6 truf tal-qtugħ.

X'inhi d-differenza bejn it-tħin tal-wiċċ u t-tħin tat-tarf?

Dawn huma l-aktar operazzjonijiet ta' tħin prevalenti, bl-użu ta' tipi differenti ta' cutters - il-mitħna tat-tarf u l-mitħna tal-wiċċ. Id-differenza bejn it-tħin tat-tarf u t-tħin tal-wiċċ hija li mitħna tat-tarf tuża kemm it-tarf kif ukoll il-ġnub tal-cutter, filwaqt li t-tħin tal-wiċċ jintuża għal qtugħ orizzontali.

Hot Tags: daħħal tnmg,tidwir, tħin, qtugħ, grooving, fabbrika,CNC, TNMG160404, TNMG 1604, TNMG 16, TNMG 22 04 08, TNMG 160408