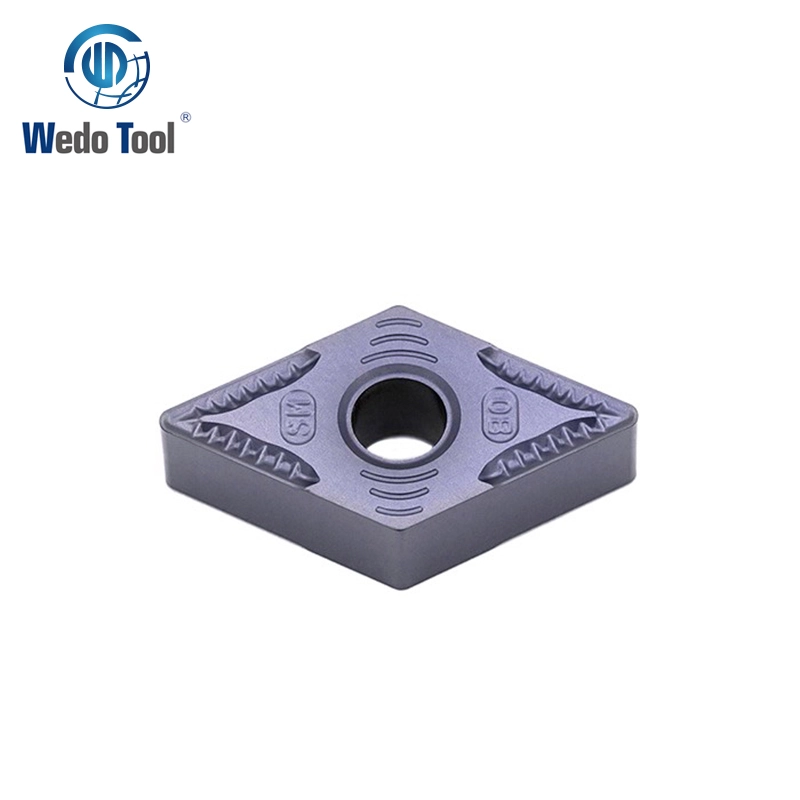

- Jeneng produk: Sisipan SNMG

- Seri: SNMG

- Chip-Breakers: AM/AR/BF/BM/BR/CM/DM

DESCRIPTION

Informasi produk:

Turing masang SNMG. sisipan kothak 90 ° pindho sisi. Sudut relief 0 derajat. Piranti karbida padhet nawakake umur alat sing dawa lan kecepatan pemotongan luwih cepet tinimbang substrat liyane, nanging luwih rapuh lan kudu digunakake kanthi sistem nyekel alat sing kaku. Nyedhiyakake umur alat sing luwih dawa tinimbang kelas sing ora dilapisi. Digunakake ing macem-macem bahan lan aplikasi.

Spesifikasi:

Aplikasi | Jinis | Ap (mm) | Fn (mm / rev) | sasmita | |||||||||||

CVD | PVD | ||||||||||||||

WD4215 | WD4315 | WD4225 | WD4325 | WD4235 | WD4335 | WD1025 | WD1325 | WD1525 | WD1328 | WR1010 | WR1325 | ||||

P Semi Finishing | SNMG120404-AM | 1.00-5.00 | 0.12-0.40 | ● | O | ● | O | O | |||||||

SNMG120408-AM | 1.20-5.00 | 0.15-0.55 | ● | O | ● | O | O | ||||||||

SNMG120412-AM | 1.50-5.00 | 0.20-0.55 | ● | O | ● | O | O | ||||||||

SNMG150612-AM | 2.00-7.00 | 0.30-0.65 | ● | O | ● | O | O | ||||||||

●: Rekomendasi Kelas

O: Kelas Pilihan

Aplikasi | Jinis | Ap (mm) | Fn (mm / rev) | sasmita | |||||||||||

CVD | PVD | ||||||||||||||

WD4215 | WD4315 | WD4225 | WD4325 | WD4235 | WD4335 | WD1025 | WD1325 | WD1525 | WD1328 | WR1010 | WR1325 | ||||

P Mesin Kasar | SNMG120408-AR | 2.50-6.00 | 0.25-0.70 | ● | O | ||||||||||

SNMG120412-AR | 2.50-6.00 | 0.30-0.70 | ● | O | |||||||||||

SNMG120416-AR | 2.50-6.00 | 0.40-0.70 | ● | O | |||||||||||

SNMG150612-AR | 2.15-6.40 | 0.25-0.50 | ● | O | |||||||||||

SNMG190612-AR | 2.15-6.40 | 0.25-0.50 | ● | O | |||||||||||

SNMG190616-AR | 2.85-7.60 | 0.30-0.65 | ● | O | |||||||||||

●: Rekomendasi Kelas

O: Kelas Pilihan

Aplikasi | Jinis | Ap (mm) | Fn (mm / rev) | sasmita | |||||||||||

CVD | PVD | ||||||||||||||

WD4215 | WD4315 | WD4225 | WD4325 | WD1025 | WD1325 | WD1525 | WD1328 | WR1010 | WR1325 | WR1525 | WR1330 | ||||

M Rampung | SNMG120404-BF | 0.25-3.20 | 0.05-0.15 | ● | ● | O | O | ||||||||

SNMG120408-BF | 0.50-3.20 | 0.10-0.30 | ● | ● | O | O | |||||||||

SNMG120412-BF | 0.75-3.20 | 0.15-0.45 | ● | ● | O | O | |||||||||

●: Rekomendasi Kelas

O: Kelas Pilihan

Aplikasi | Jinis | Ap (mm) | Fn (mm / rev) | sasmita | |||||||||||

CVD | PVD | ||||||||||||||

WD4215 | WD4315 | WD4225 | WD4325 | WD1025 | WD1325 | WD1525 | WD1328 | WR1010 | WR1325 | WR1525 | WR1330 | ||||

M Semi Finishing | SNMG120404-BM | 0.30-4.20 | 0.08-0.25 | O | O | ● | O | O | |||||||

SNMG120408-BM | 0.65-4.20 | 0.15-0.45 | O | O | ● | O | O | ||||||||

SNMG120412-BM | 0.95-4.20 | 0.25-0.65 | O | O | ● | O | O | ||||||||

SNMG150608-BM | 0.65-5.20 | 0.15-0.45 | O | O | ● | O | O | ||||||||

SNMG150612-BM | 0.95-5.20 | 0.25-0.65 | O | O | ● | O | O | ||||||||

●: Rekomendasi Kelas

O: Kelas Pilihan

Aplikasi | Jinis | Ap (mm) | Fn (mm / rev) | sasmita | |||||||||||

CVD | PVD | ||||||||||||||

WD4215 | WD4315 | WD4225 | WD4325 | WD1025 | WD1325 | WD1525 | WD1328 | WR1010 | WR1325 | WR1528 | WR1330 | ||||

M Mesin Kasar | SNMG120404-BR | 0.30-4.20 | 0.08-0.25 | O | O | O | ● | ● | O | ||||||

SNMG120408-BR | 0.65-4.20 | 0.15-0.45 | O | O | O | ● | ● | O | |||||||

SNMG120412-BR | 0.95-4.20 | 0.23-0.66 | O | O | O | ● | ● | O | |||||||

SNMG150608-BR | 0.65-5.20

| 0.15-0.44 | O | O | O | ● | ● | O | |||||||

SNMG150612-BR | 0.95-5.20 | 0.23-0.66 0.23-0.66 | O | O | O | ● | ● | O | |||||||

●: Rekomendasi Kelas

O: Kelas Pilihan

Aplikasi | WD3040 | Ap (mm) | Fn (mm / rev) | sasmita | |||

CVD | |||||||

WD3020 | WD3040 | WD3315 | WD3415 | ||||

K Semi Rampung | SNMG120404-CM | 0.40-4.20 | 0.08-0.25 | ● | O | ||

SNMG120408-CM | 0.80-4.20 | 0.15-0.45 | ● | O | |||

SNMG120412-CM | 1.20-4.20 | 0.25-0.65 | ● | O | |||

●: Rekomendasi Kelas

O: Kelas Pilihan

Aplikasi | Jinis | Ap (mm) | Fn (mm / rev) | sasmita | ||||||||||||

CVD | PVD | |||||||||||||||

WD4215 | WD4315 | WD4225 | WD4325 | WD1025 | WD1325 | WD1525 | WD1328 | WR1010 | WR1520 | WR1525 | WR1028 | WR1030 | ||||

S Semi Finishing | SNMG120404-DM | 0.40-3.90 | 0.08-0.25 | O | O | O | ● | ● | O | O | ||||||

SNMG120408-DM | 0.80-3.90 | 0.15-0.45 | O | O | O | ● | ● | O | O | |||||||

SNMG120412-DM | 1.20-3.90 | 0.25-0.65 | O | O | O | ● | ● | O | O | |||||||

SNMG120416-DM | 1.80-3.90 | 0.30-0.90 | O | O | O | ● | ● | O | O | |||||||

SNMG150608-DM | 0.80-3.90 | 0.15-0.45 | O | O | O | ● | ● | O | O | |||||||

SNMG150612-DM | 1.20-3.90 | 0.25-0.65 | O | O | O | ● | ● | O | O | |||||||

SNMG150616-DM | 1.80-3.90 | 0.30-0.90 | O | O | O | ● | ● | O | O | |||||||

●: Rekomendasi Kelas

O: Kelas Pilihan

Aplikasi:

Aplikasi kanggo ngowahi lan panggilingan baja karbon lan paduan, baja alat lan baja tahan karat.

FAQ:

Cara milih sisipan ngowahi sing bener?

Pilih insert geometri adhedhasar operasi sing dipilih, contone finishing.

Pilih amba irung paling gedhe bisa ing sisipan kanggo kekuatan lan ekonomi.

Pilih ukuran sisipan gumantung saka ambane potong

Pilih radius irung paling gedhe kanggo kekuatan insert.

Apa bedane antarane panggilingan pasuryan lan panggilingan pungkasan?

Iki minangka rong operasi panggilingan sing paling umum, saben nggunakake macem-macem jinis pemotong - lan pabrik lan pabrik pasuryan. Bentenipun antarane panggilingan mburi lan panggilingan pasuryan yaiku pabrik pungkasan nggunakake ujung lan pinggir pemotong, dene panggilingan pasuryan digunakake kanggo nglereni horisontal.

Hot Tags: sisipan snmg, ngowahi,panggilingan, nglereni, grooving, pabrik,CNC